Lot

521

Manufacturer

GREENLINE INDUSTIRES

Name

BIODIESEL PROCESSING LINE

Model

CF-3

Serial

Description

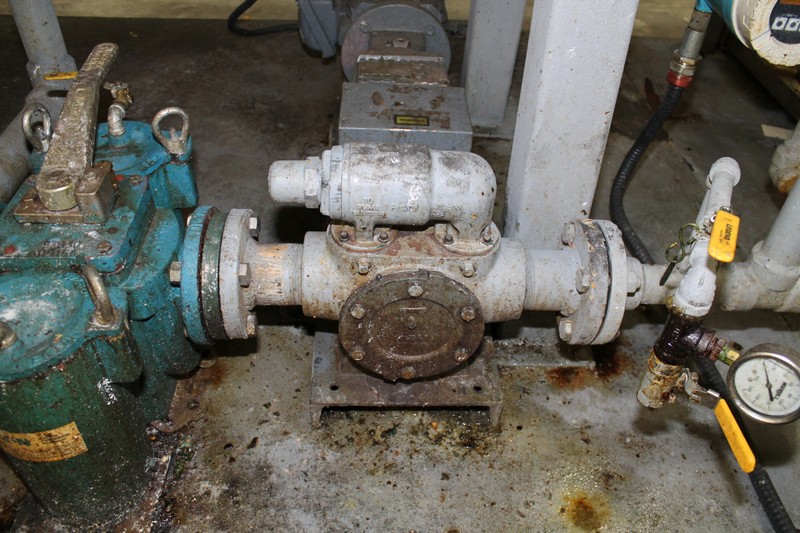

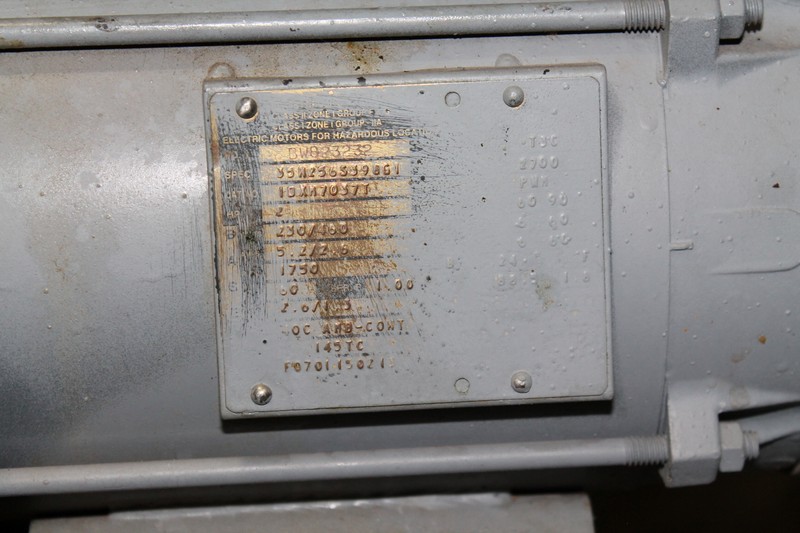

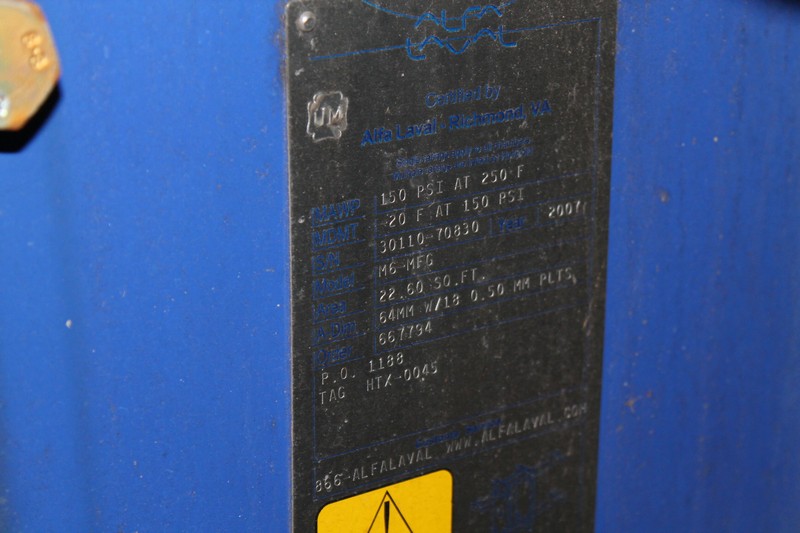

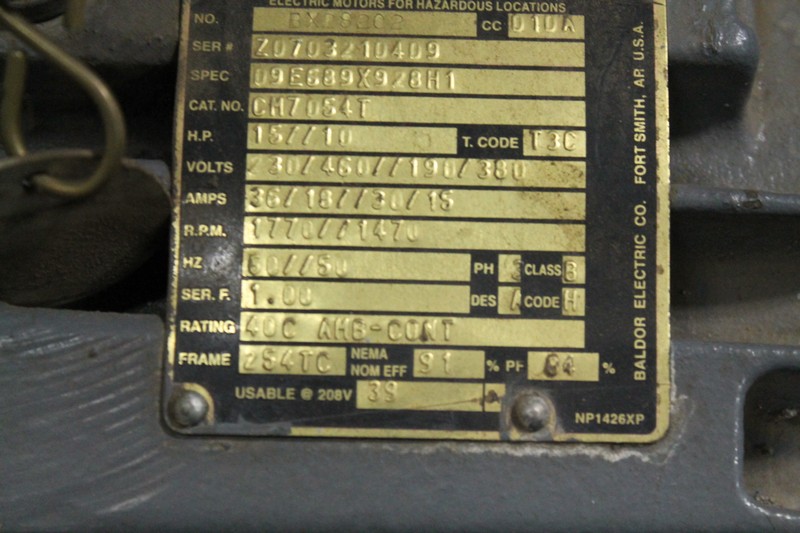

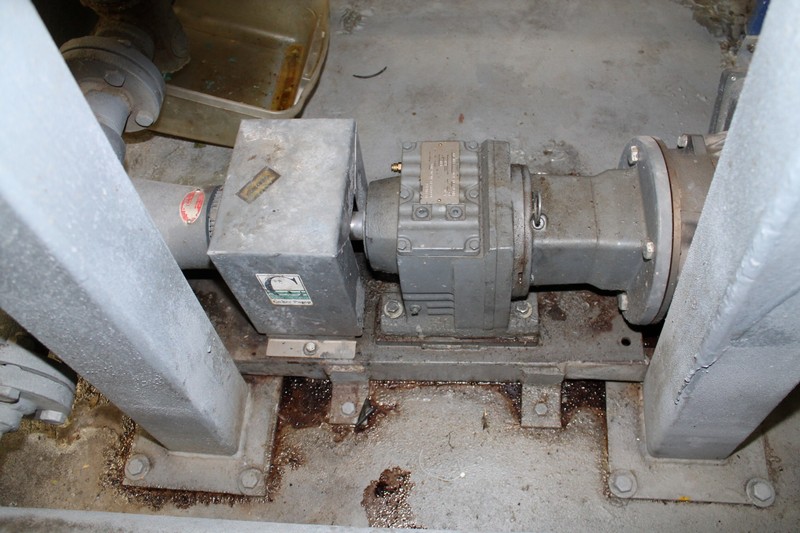

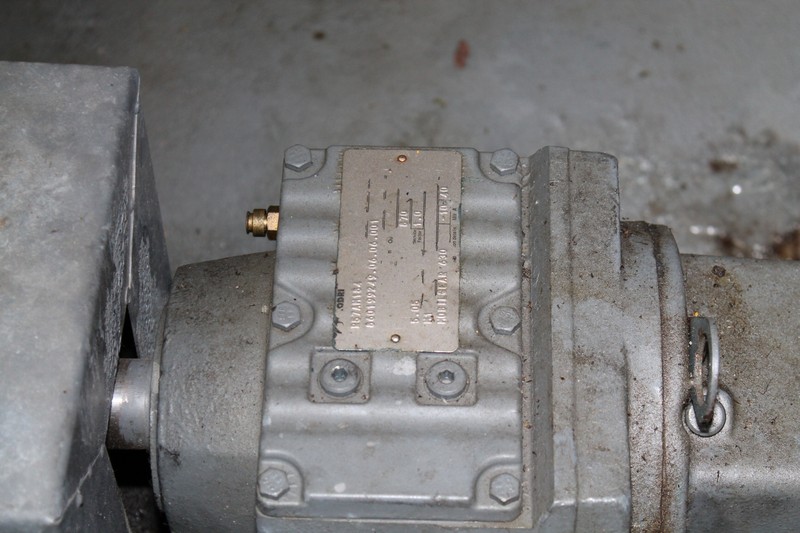

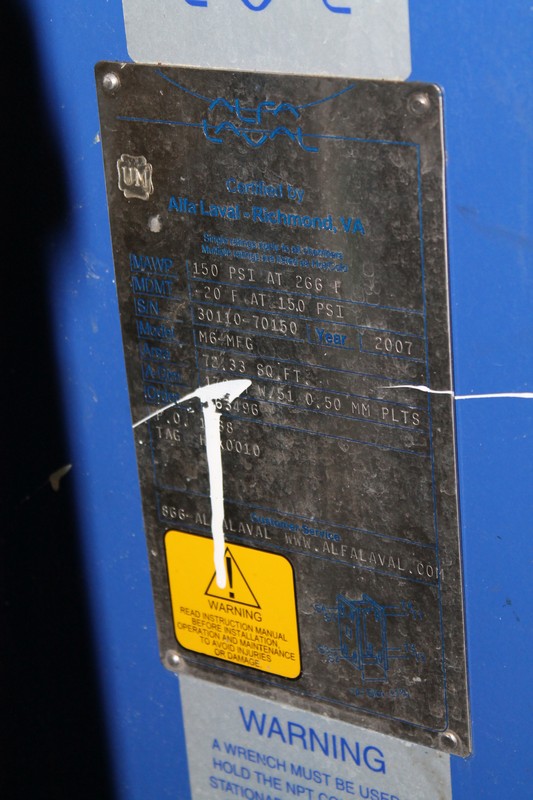

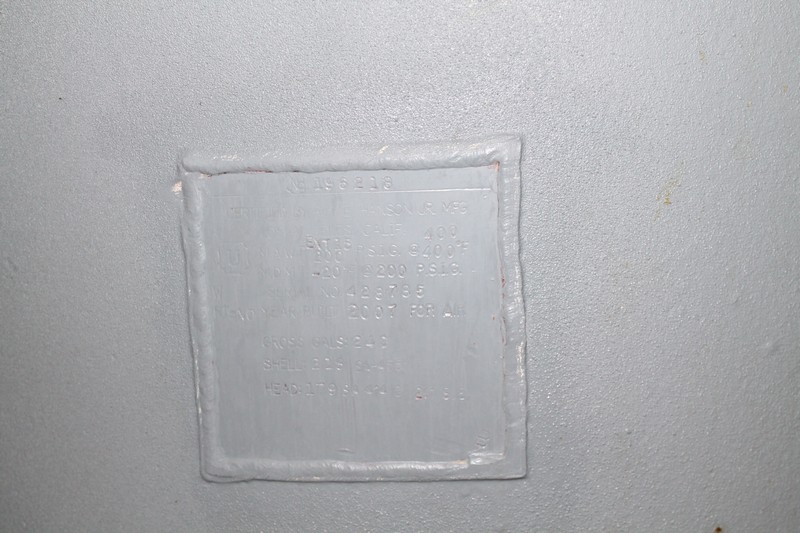

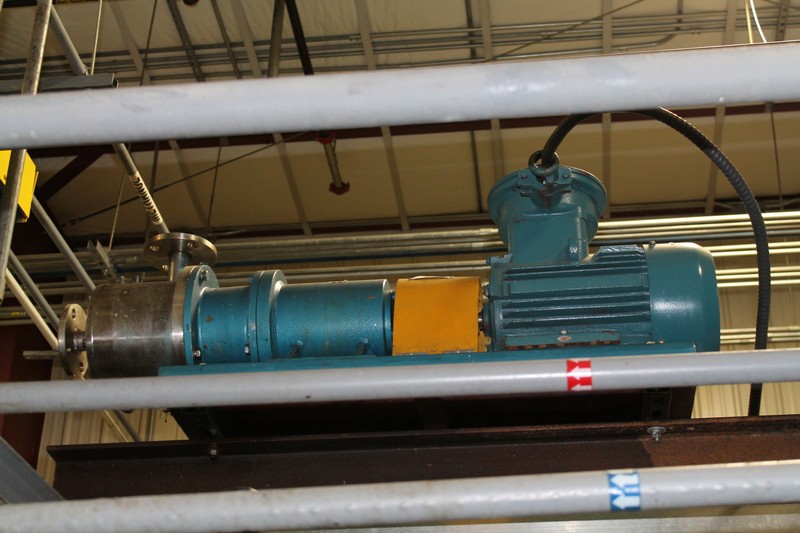

3- Million Gallons/Year name plate capacity, Consisting of but not necessarily limited to: 10- 8 ft. long x 6 ft. wide x 7 ft. 9 in. high Fabricated Steel Process Modules; Each Module Uniquely Equipped, having the following: With VAPOR RECOVERY CONDENSER UNIT Module 1- TRAVANINI Model TRHC 40-190/O/RX, Liquid Ring Vacuum Pump, (Cold) s/n AH406 DOPEL, powered by BALDOR 10 hp Electric Motor; ALFA LAVAL Plate Type Heat Exchanger; MC 1-1/4 in. Diaphragm Pump; 80 gal. (est.) Vertical Receiver Tank, Skirted; with All Required and Necessary Related Piping, control and Utility Plumbing and Wiring; 1- GUARDIAN EQUIPMENT Emergency Decontamination Station with Shower Head and Eye Wash Basin. With VAPOR RECOVERY CONDENSER UNIT Module 2 - TRAVANINI Model TRHB 50-280/C/RA Liquid Ring Vacuum Pump (Warm), s/n AS390-E1PY1, powered by BALDOR 15 hp Electric Motor; 2- ALFA LAVAL Model M6-MFG Plate Type Heat Exchanger Process Heaters; 2- MC 1-1/4 in. Diaphragm Pump; 80 gal. (est.) Vertical Receiver Tank, Skirted; with all Required, Necessary Related Plumbing, Valves, Remote Controlled, Powered and Manual; Electrical Power Distribution and Control Wiring, Wiring Harness Layout Trays, and Conduits. With ADU METHANOL RECOVERY UNIT Module 3 - With Dryer, ALFA LAVAL Model M6-MFG Plate Type Heat Exchanger; VIKING/COKER Model AK4195 Gear Type Pump powered through a Reduction Gear Box and by BALDOR 3- hp Electric Motor; Vertical Electric Heater having CALORIC Heating Element; with all Required and Necessary Related Plumbing, Valves, Remote Controlled, Powered and Manual; Electrical Power Distribution and Control Wiring, Wiring Harness Layout Trays, and Conduits. With 1ST STAGE ION WASH UNIT Module 4 - Ion Wash Module with 300 gal. (est.) Vertical Wash Tank, Skirted, Insulated; BERKELEY 1-3/4 in. x 1 in. Centrifugal Pump, Stainless Steel, powered by 5 hp (est.) Electric Motor, Vertical Electric Heater having Caloric Heat Element, with all Required and Necessary Related Plumbing, Valves, Remote Controlled, Powered and Manual, Electrical Power Distribution and Control Wiring, Wiring Harness Layout Trays and Conduits. With 1ST STAGE ION WASH UNIT Module 5 - Ion Wash Module with 300 gal. (est.) Vertical Wash Tank, Skirted, Insulated; GOULDS 2 in. x 1 in. Centrifugal Pump powered by BALDOR 10 hp (est.) Electric Motor; WILDEN 3-1/4 in. x 2-1/4 in. Diaphragm Pump; with all Required, Necessary Related Plumbing, Valves, Remote Controlled, Powered and Manual; Electrical Power Distribution and Control Wiring, Wiring Harness Layout Trays and Conduits. With 2ND STAGE ION WASH UNIT Module 6 - 1- 500 gal. Vertical Tank, Skirted; BERKELEY 1-3/4 in. x 2-1/4 in. Diaphragm Pump, Stainless Steel powered by 5 hp (est.) Electric Motor; Vertical CALORIC Electric Heater; 36 in. x 36 in. x 36 in. Fabricated Steel Tank with all Required and Related Plumbing, Valves, Remote Controlled, Powered, and Manual; Electrical Power Distribution and Control Wiring, Wiring Harness Layout Trays and Conduits. With 2ND STAGE ION WASH UNIT Module 7 - 1- 500 gal. Vertical Tank, Skirted; BERKELEY 1-3/4 in. x 2-1/4 in. Diaphragm Pump, Stainless Steel powered by 5 hp (est.) Electric Motor; Vertical Caloric Electric Heater; with all Required Related Plumbing, Valves, Remote Controlled, Powered, and Manual; Electrical Power Distribution and Control Wiring, Wiring Harness Layout Trays and Conduits. With CATALYST AND METHANOL DOSING UNIT Module 8 - Catalyst and Methanol Dosing Control Skid consisting of but not necessarily limited to: 4- NEPTUNE CHEMICAL PUMP CO. Model 532-D-N3-FA-T, each powered by 1-1/2 hp Electric Motor; Dosing Pumps and 4- ENDRESS HAUSER Pro Mass 80 Coriolis Flowmeters; with all Required and Necessary Related Plumbing, Valves, Remote Controlled, Powered and Manual; Electrical Power Distribution and Control Wiring, Wiring Harness Layout Trays and Conduits. With Module 9 - ALFA LAVAL Model M6-MFG Plate Type Heat Exchanger, Insulated; VIKING/COKER Model AK4195 Gear Type Pump powered through a Reduction Gear Box and by BALDOR 3- hp Electric Motor; Vertical Electric Heater having Caloric Heating Element; 2- EATON Dosing Unit Filters, Model 53; 1- 2-1/2 in. x 2-1/2 in. Diaphragm Pump; with all Required and Necessary Related Plumbing, Valves, Remote Controlled, Powered and Manual; Electrical Power Distribution and Control Wiring, Wiring Harness Layout Trays, and Conduits. With Module 10 - VIKING Model HL4195 Gear Type Pump powered by BALDOR 3 hp (est.) Electric Motor; 2- EATON Cartridge Type Filters; ALFA LAVAL Model M6-MFG Plate Type Heat Exchanger with all Required and Necessary Related Plumbing, Valves, Remote Controlled, Powered and Manual, Electrical Power Distribution and Control Wiring, Wiring Harness Layout Trays and Conduits. (NOTE: This Heat Exchanger IS NOT Incorporated in the Process Flow. It is only temporarily placed on the subject Skid.)