Lot

1

Manufacturer

ARIEL CORPORATION

Name

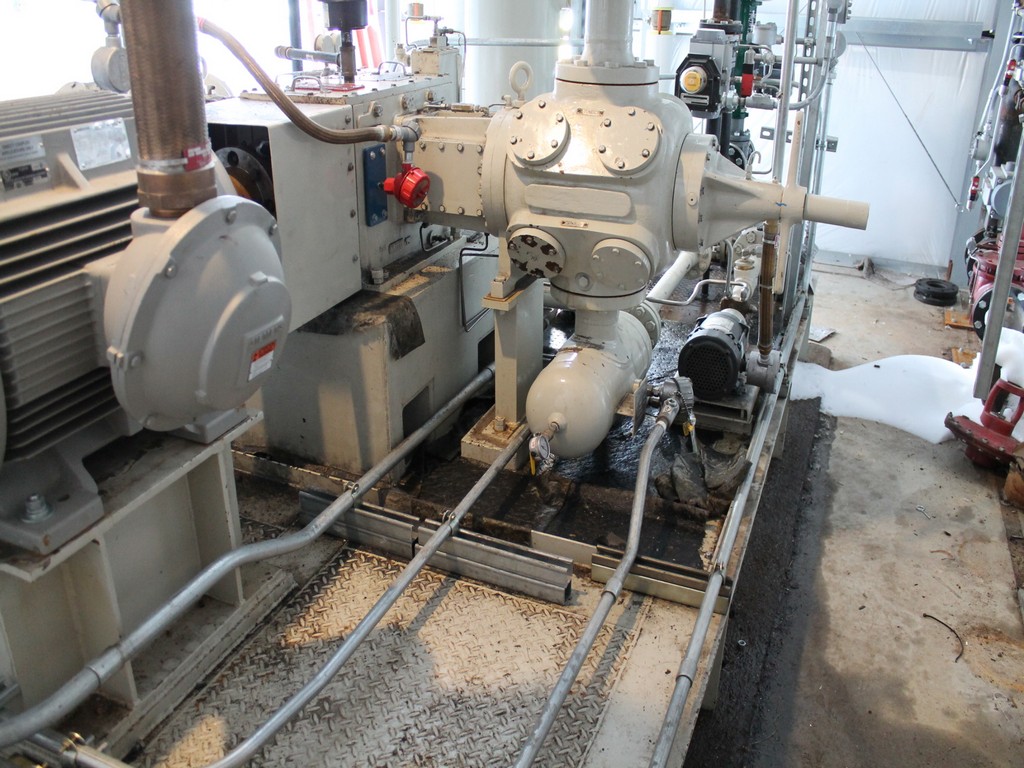

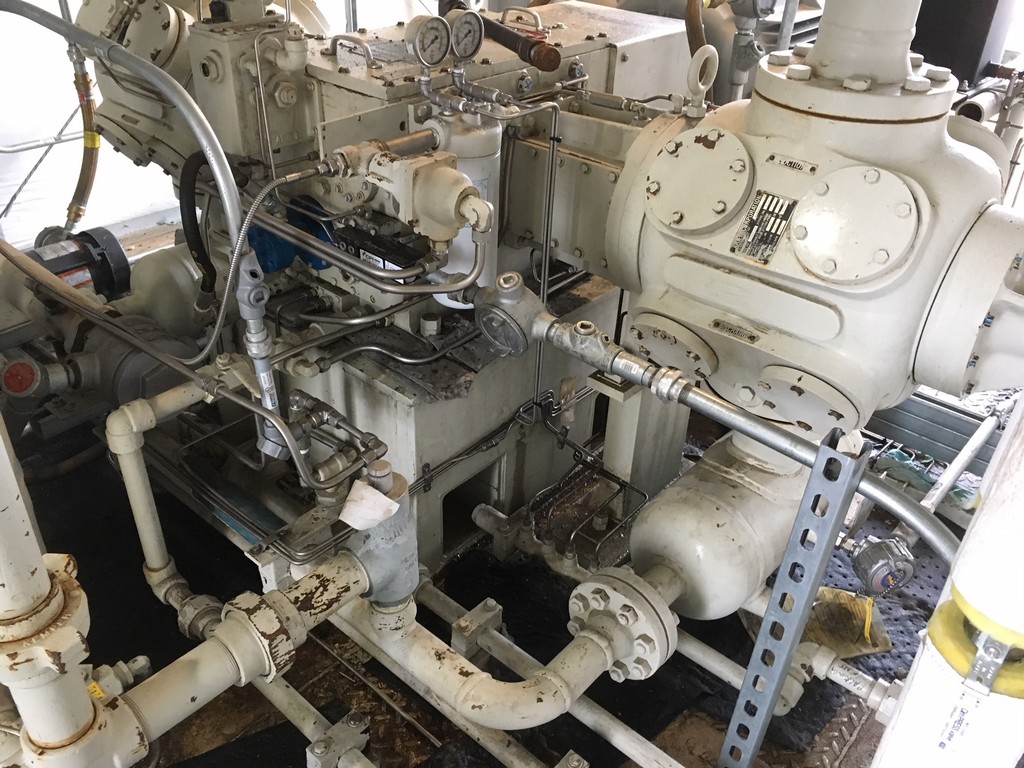

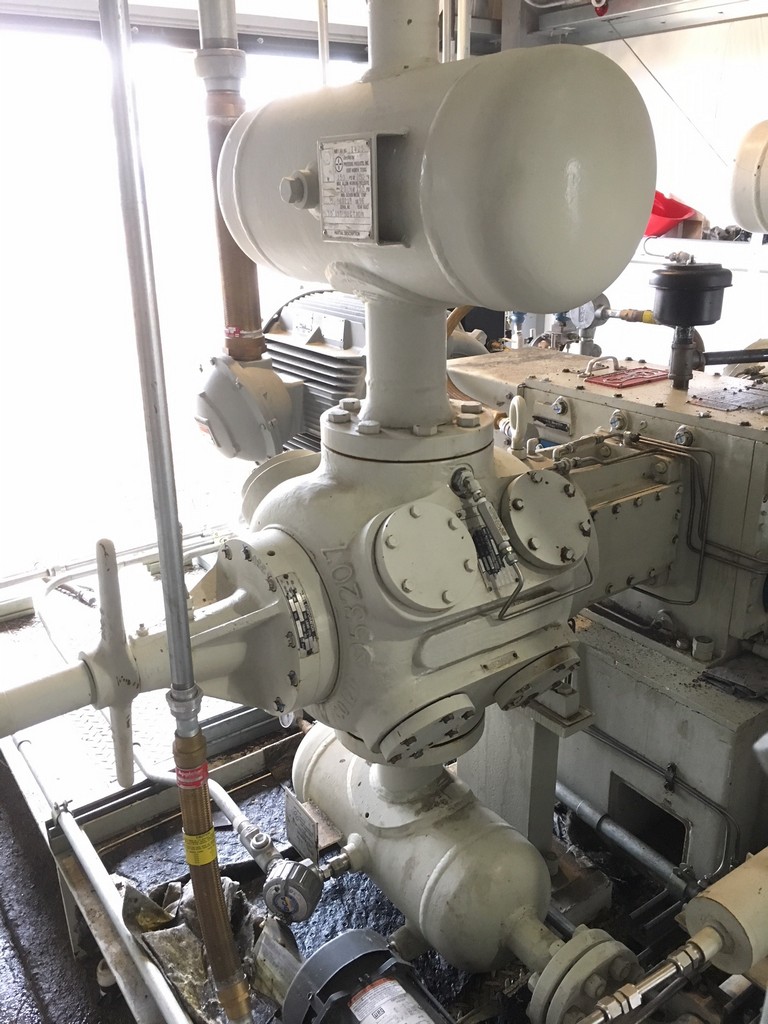

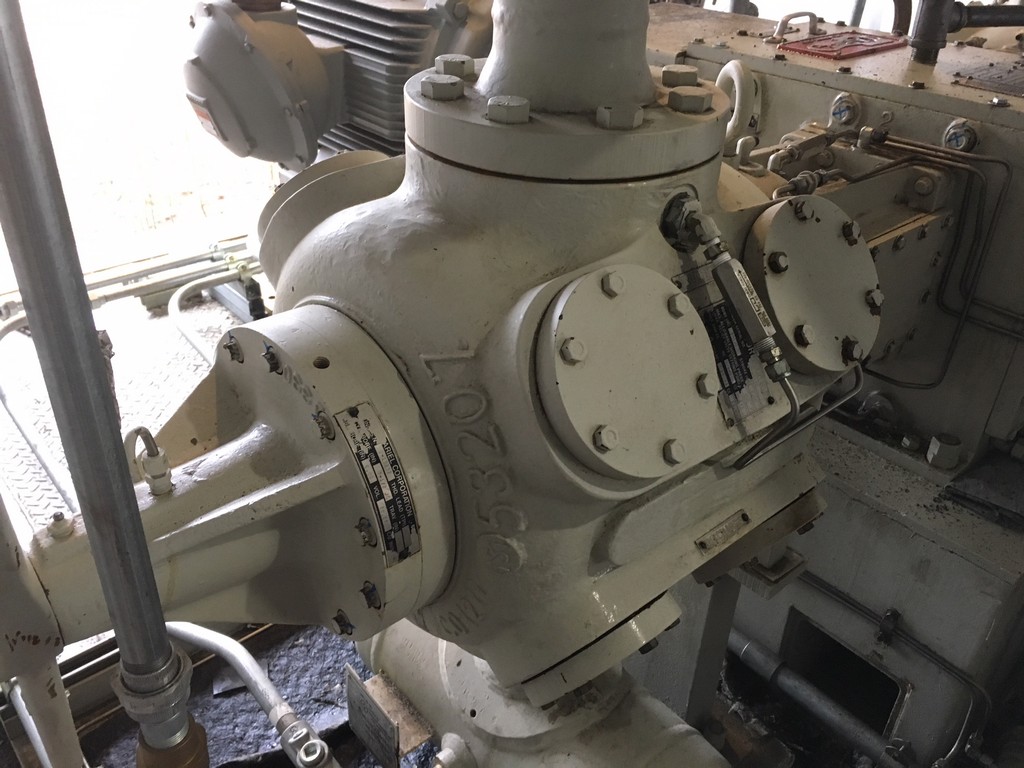

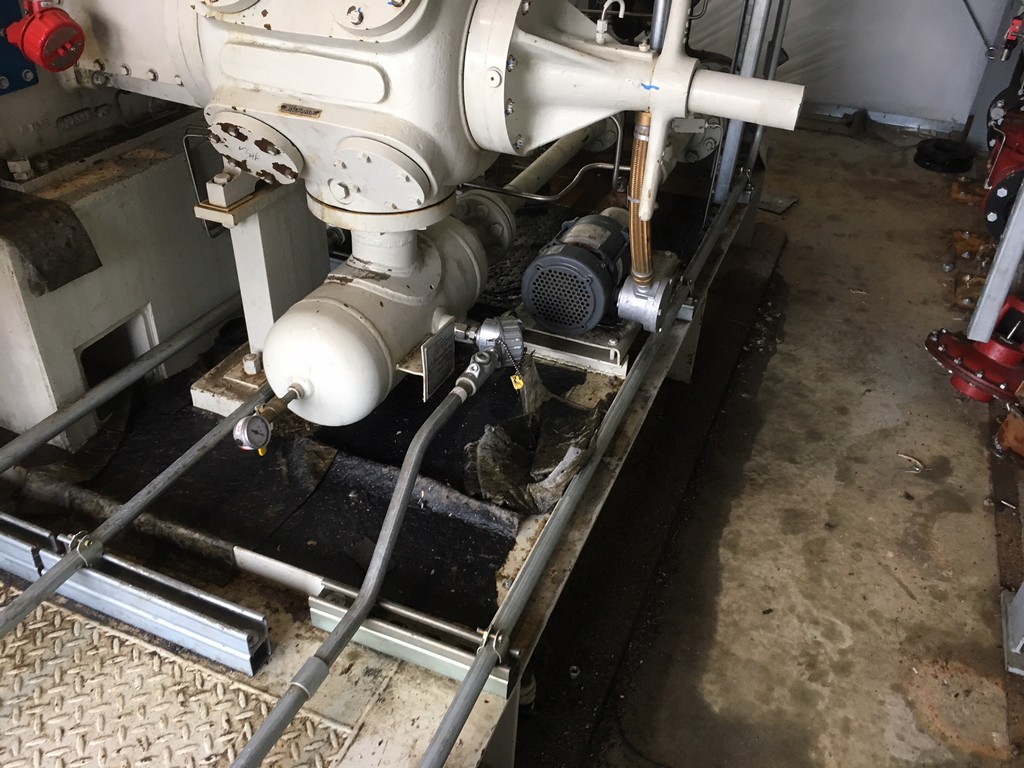

NATURAL GAS RECIPROCATING 2-THROW COMPRESSOR

Model

JGA/2

Serial

F-11050 (Mfg. March-1996)

Description

3 In. Stroke, Maximum Rated Speed 1,800RPM, Minimum Rated Speed 900RPM, Maximum Total Rod Load (Compression + Tension) 18,000 lbs., Normal Lube Oil Pressure 50psi, Lube Oil Pressure Shutdown Setting 25 psi, Maximum Lube Oil Temperature 190 degrees F.

1st Suction 10" NAT'L BD. NO. 1424 U Stamp, 150 psi at 150 degrees F Max Allow. Working Pressure; -20 degrees F at 150psi, Min. Design Metal Temp. S/N 96121A (Mfg. 1996); S/N U-15231 Thd. Lead (TPI) .083, Cyl. Bore (In.) 7-1/2 JG, Trav. (In.) 2.94, Unl. Bore (In.) 6.00, Vol. 28.27 Cu. In./In.; Certified by Pressure Products, Inc. Fort Worth, Texas.

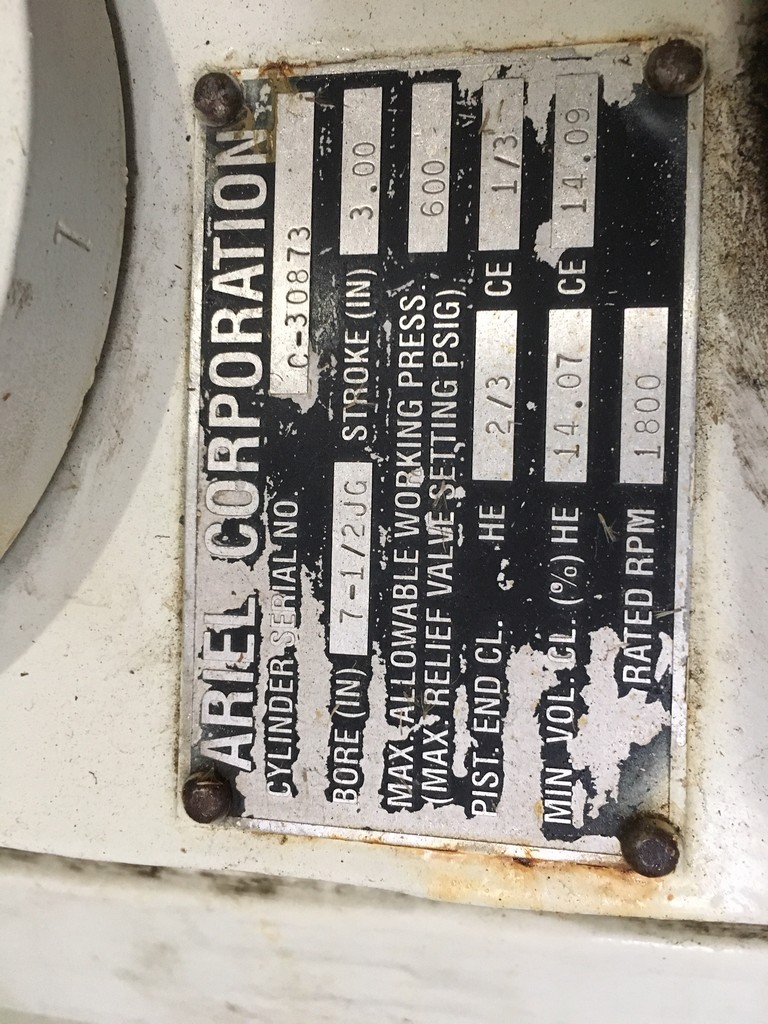

1st Cylinder S/N: C-30873, Bore (In.) 7-1/2 JG, Stroke (In.) 3.00, Max. Allowable Working Pressure (Max. Relief Valve Setting psig) 600, Pist. End. Cl. HE 2/3, CE 1/3, Min. Vol. CL (%) HE 14.07, CE 14.09, Rated RPM 1800.

1st Discharge 8" NAT'L BD. NO. 1426 U Stamp, 250 psi at 350 degrees F Max Allow. Working Pressure, -20 degrees F at 250 degrees psi Min. Design Metal Temp. S/N 96122 (Mfg. 1996); Certified by Pressure Products, Inc. Fort Worth, Texas.

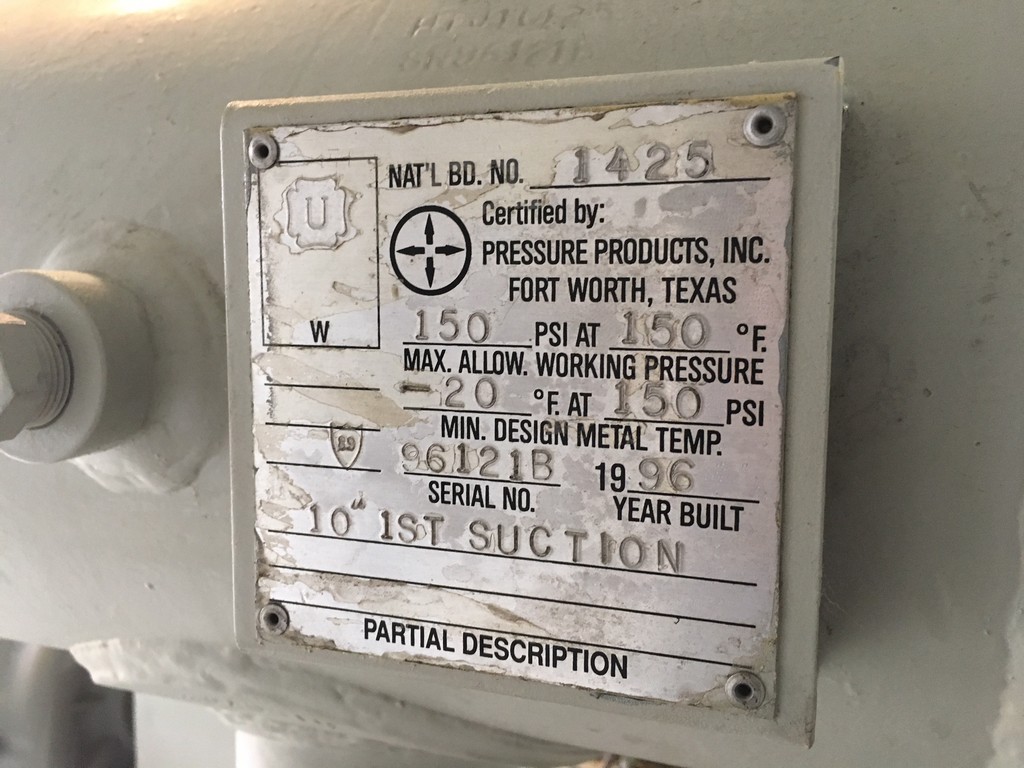

1st Suction 10" NAT'L BD. NO. 1425 U Stamp, 150 psi at 150 degrees F Max Allow. Working Pressure; -20 degrees F at 150 psi, Min. Design Metal Temp. S/N 96121B (Mfg. 1996); S/N U-15232 Thd. Lead (TPI) .083, Cyl. Bore (In)7-1/2 JG, Trav. (In.) 2.94, Unl. Bore (In.) 6.00, Vol. 28.27 Cu. In/In.; Certified by Pressure Products, Inc. Fort Worth, Texas.

1st Cylinder S/N: C-30870, Bore (In.) 7-1/2 JG, Stroke (In.) 3.00, Max. Allowable Working Pressure (Max. Relief Valve Setting psig) 600, Pist. End. Cl. HE 2/3, CE 1/3, Min. Vol. CL (%) HE 14.07, CE 14.09, Rated RPM 1800.

1st Discharge 8" NAT'L BD. NO. 1427 U Stamp, 250 psi at 350 degrees F Max Allow. Working Pressure, -20 degrees F at 250 degrees psi Min. Design Metal Temp. S/N 96123 (Mfg. 1996); Certified by Pressure Products, Inc. Fort Worth, Texas.

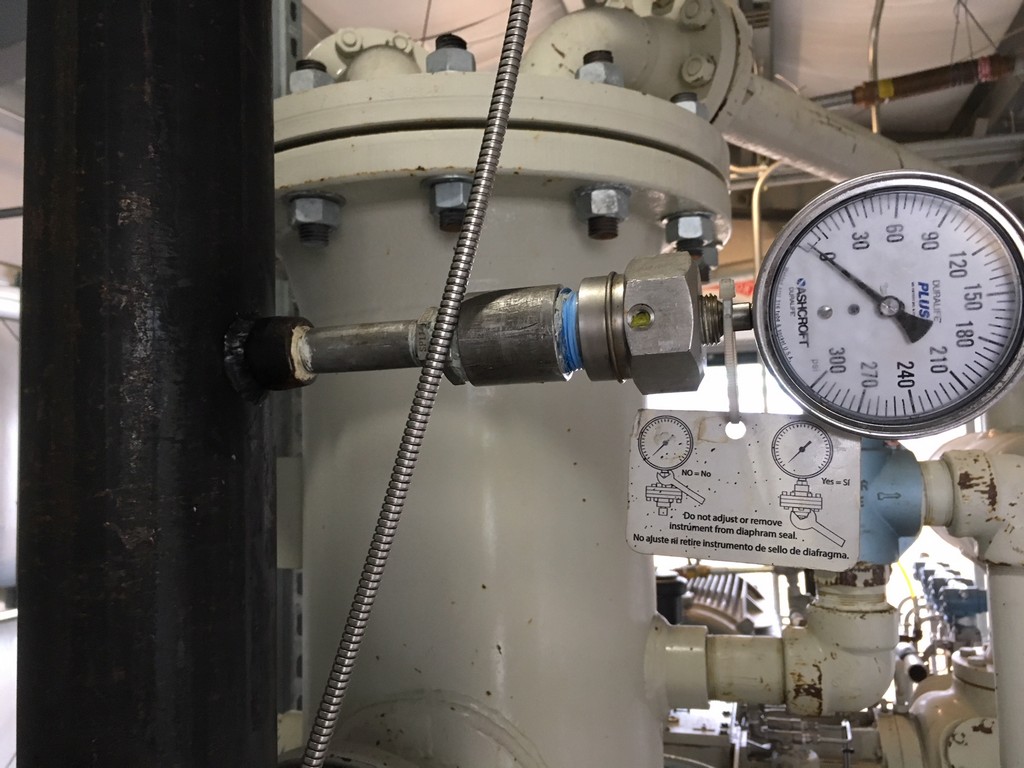

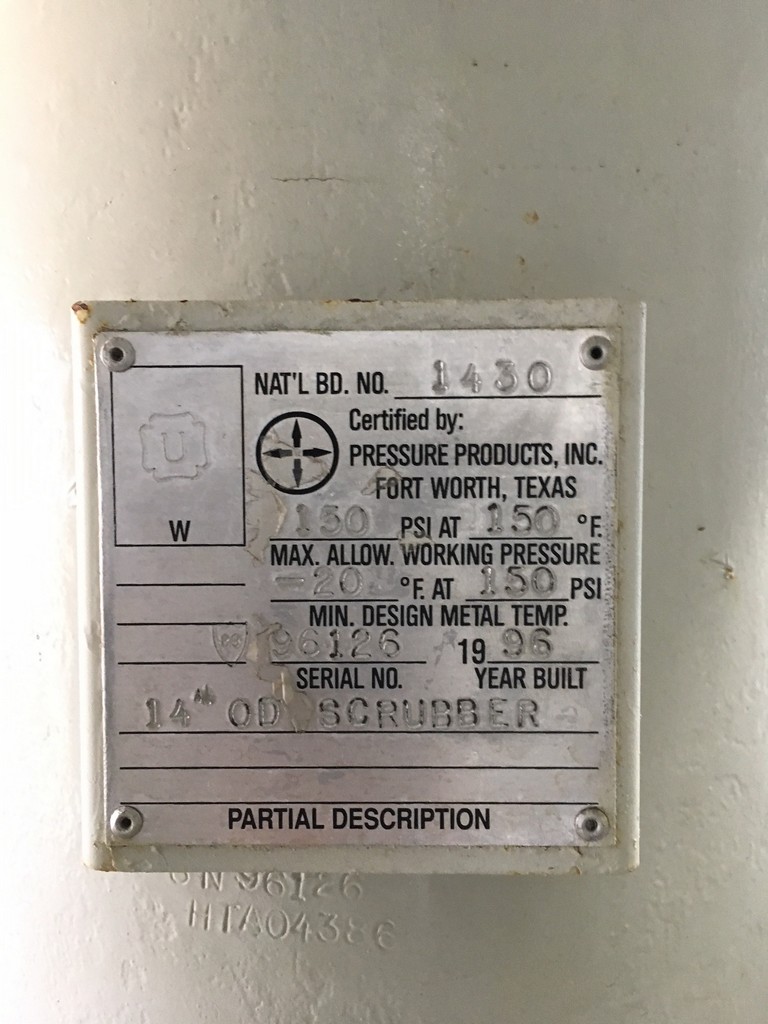

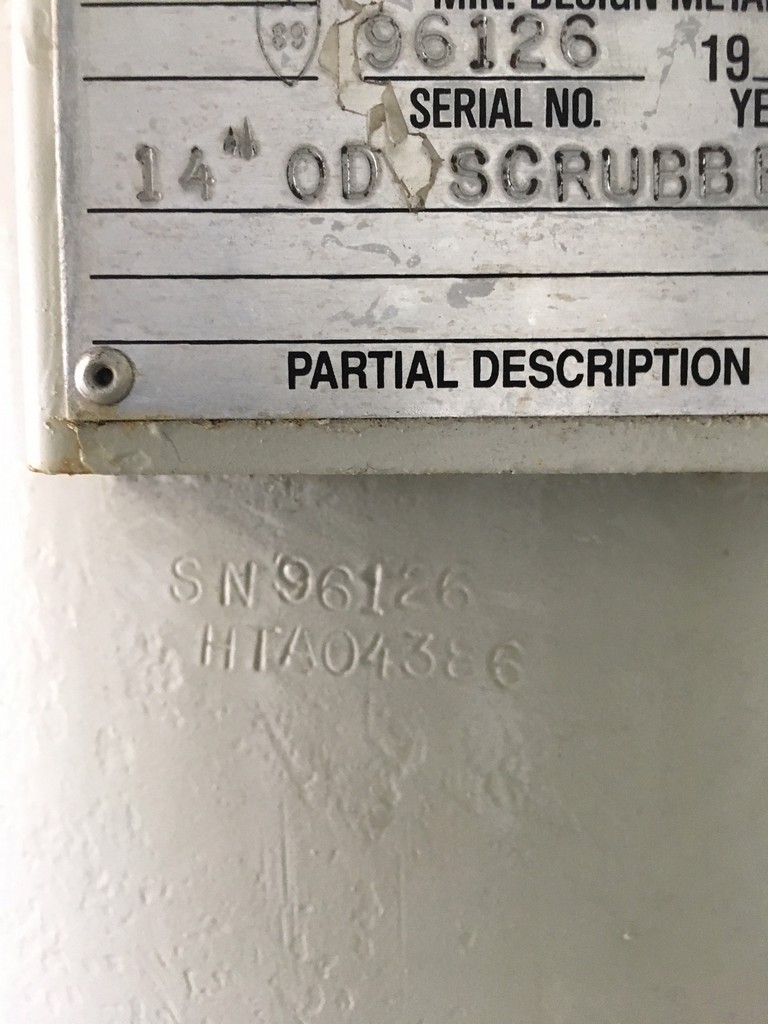

14" OD SCRUBBER- NAT'L BD. NO. 1430 U Stamp, 150 psi at 250 degrees F Max Allow. Working Pressure, -20 degrees F at 150 psi Min. Design Metal Temp., S/N 96126 (Mfg. 1996).

BASCO/AMERICAN PRECISION INDUSTRIES HEAT EXCHANGER- NAT'L BD. NO. 43400 U Stamp, 150 psi AT 100 degrees F Max Working Pressure Shell, 300psi at 400 degrees F Max Working Pressure Tube, 20 degrees F at 150 psi M.D.M.T Shell Side, 20 degrees F at 300 psi M.D. M. T Tube Side, S/N: 961334-0101, Part No. 8A76A06048 (Mfg. 1996, Size 06048, Certified by BASCO.

MURPHY EXPLOSION PROOF OIL LEVEL MAINTAINER WITH 4 GAL. APPROX. OIL RESERVOIR TANK EQUIPPED WITH SIGHT GAUGE AND OIL PUMP WITH 5GPM FLOW RATE- Model LM 305-EX, S/N 65000395732, Dual Switch, Alarm on Low Level and Shut Down on Low-Low Level.

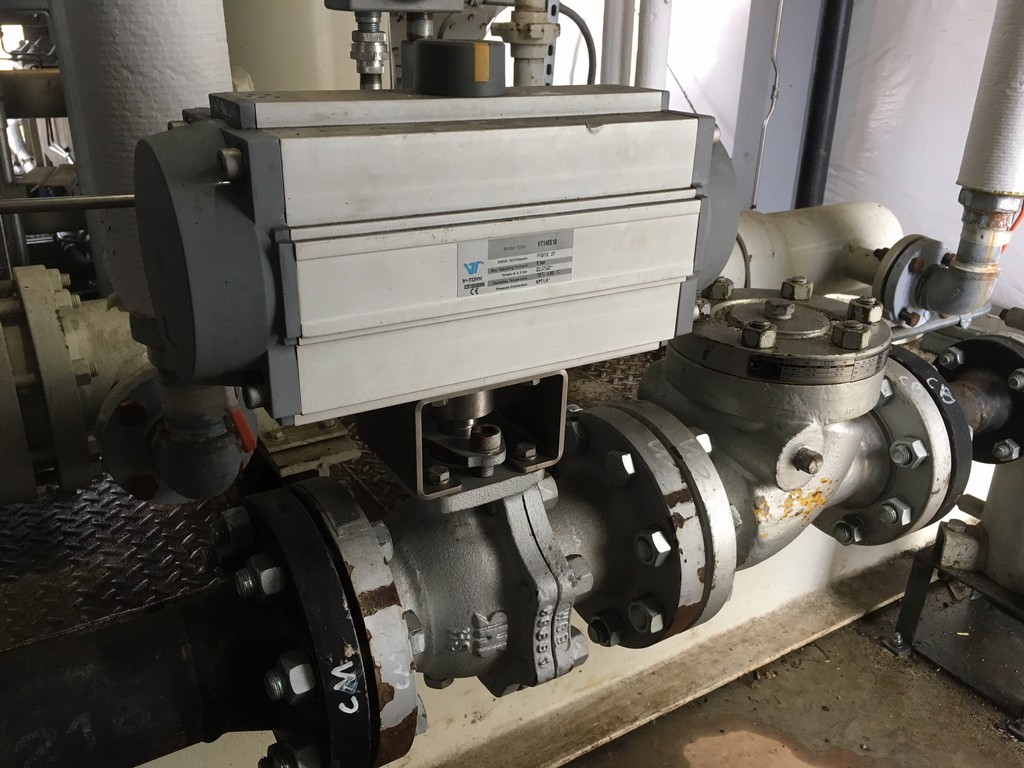

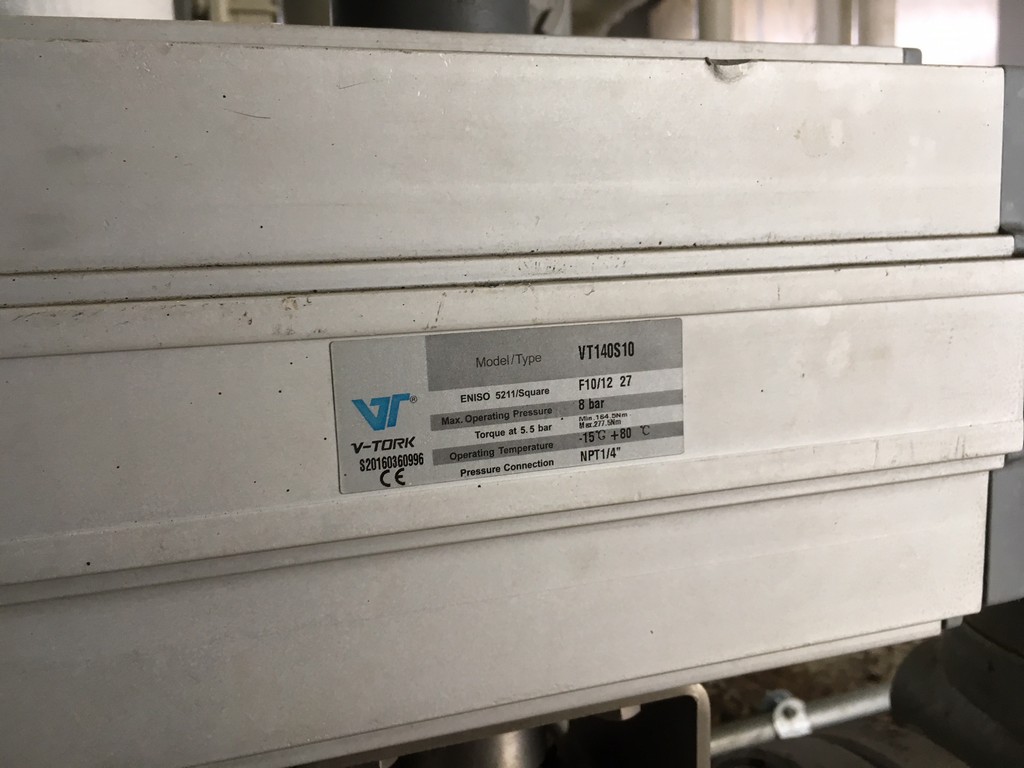

V-TORK PNEUMATIC ACTUATOR WITH FLOW CUT OFF BALL VALVE- Model- VT140S10, S/N S20160360996. ENISO 5211/Square F10/12 27, Max Operating Pressure 8 Bar, Operating Temperature -15 degrees C to 80 degrees C, Pressure Connection NPT .25".

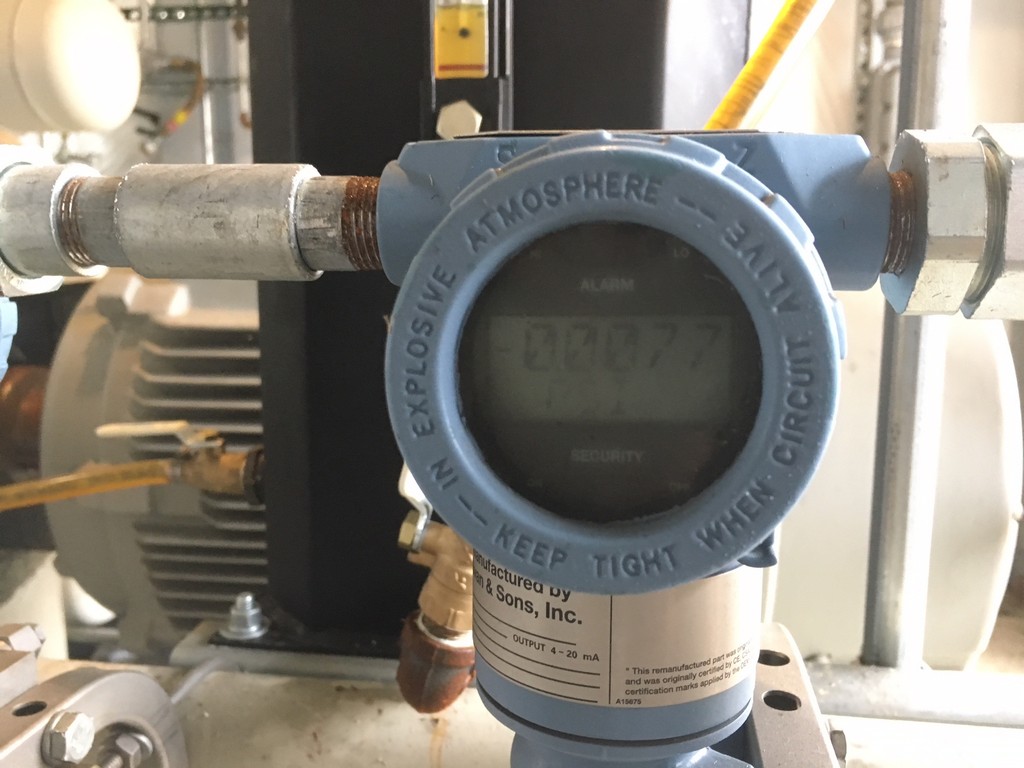

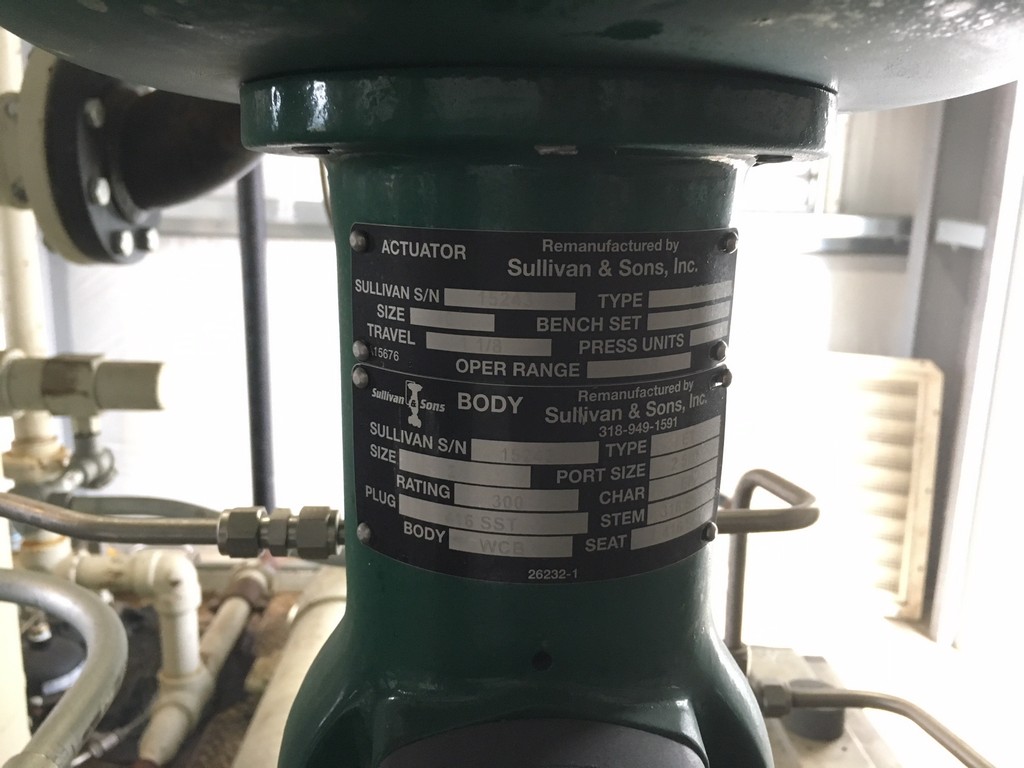

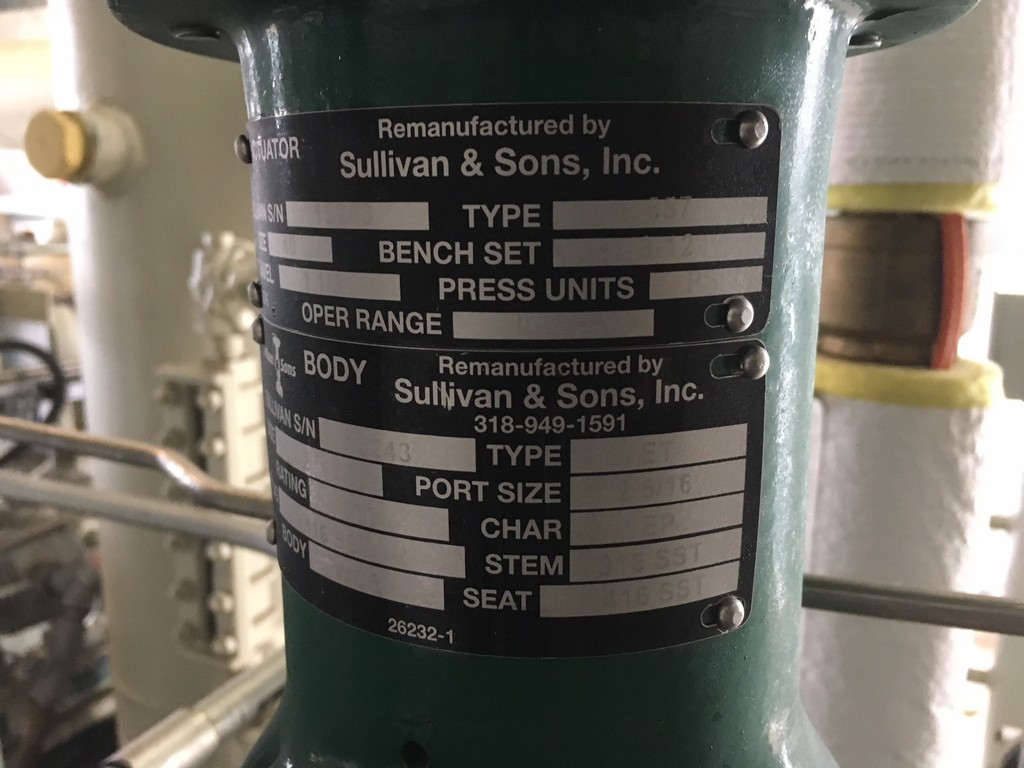

FISHER ELECTRO PNEUMATIC SLIDING STEM ACTUATOR CONTROL VALVE WITH FISHER FIELDVUE DIGITAL SMART POSITIONER- Remanufactured by Sullivan & Sons, Inc., S/N 15243.

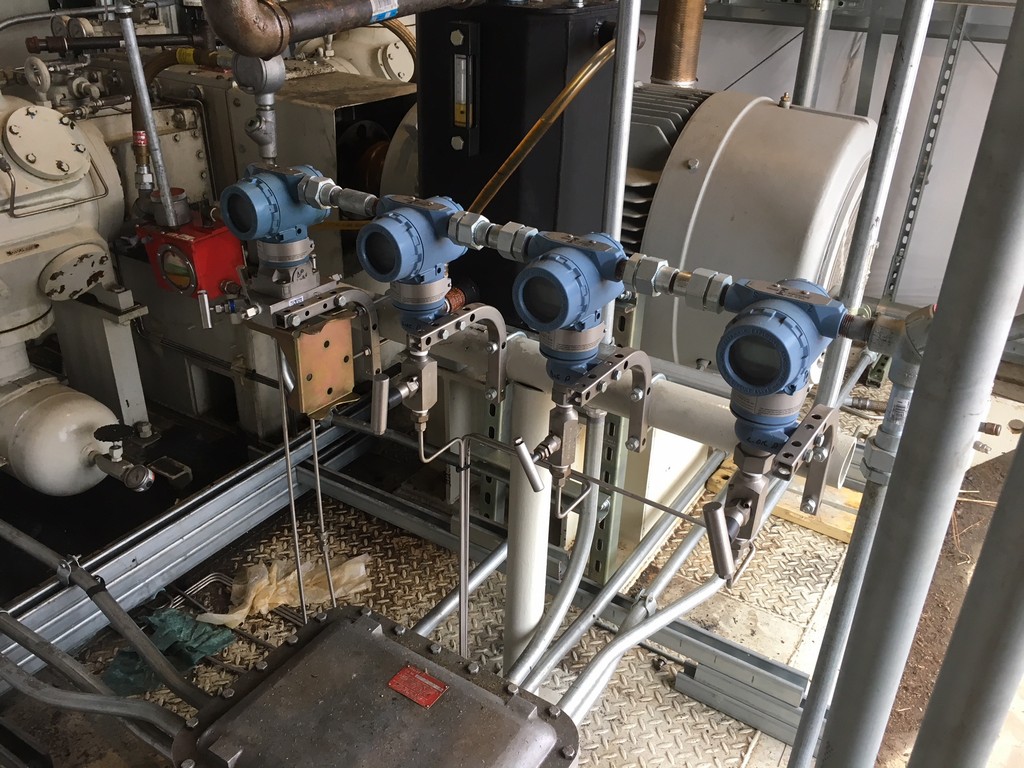

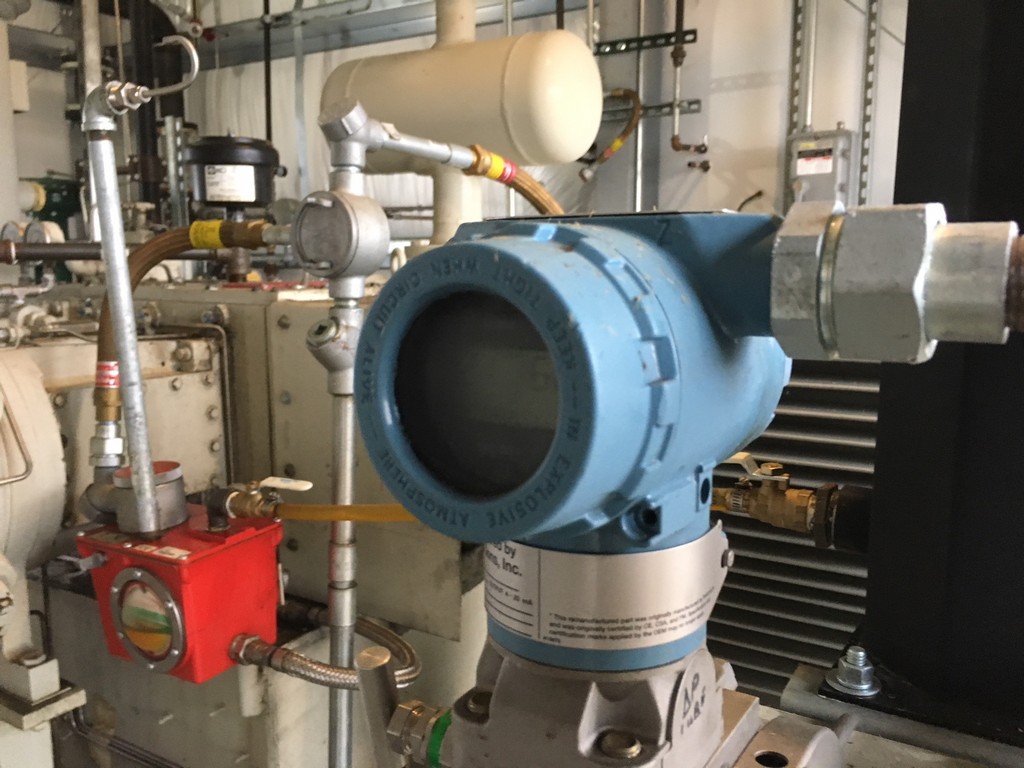

4-ENDRESS HAUSER DIGITAL FLOW METERS PEDESTAL MOUNTED-Remanufactured by Sullivan & Sons, Inc.

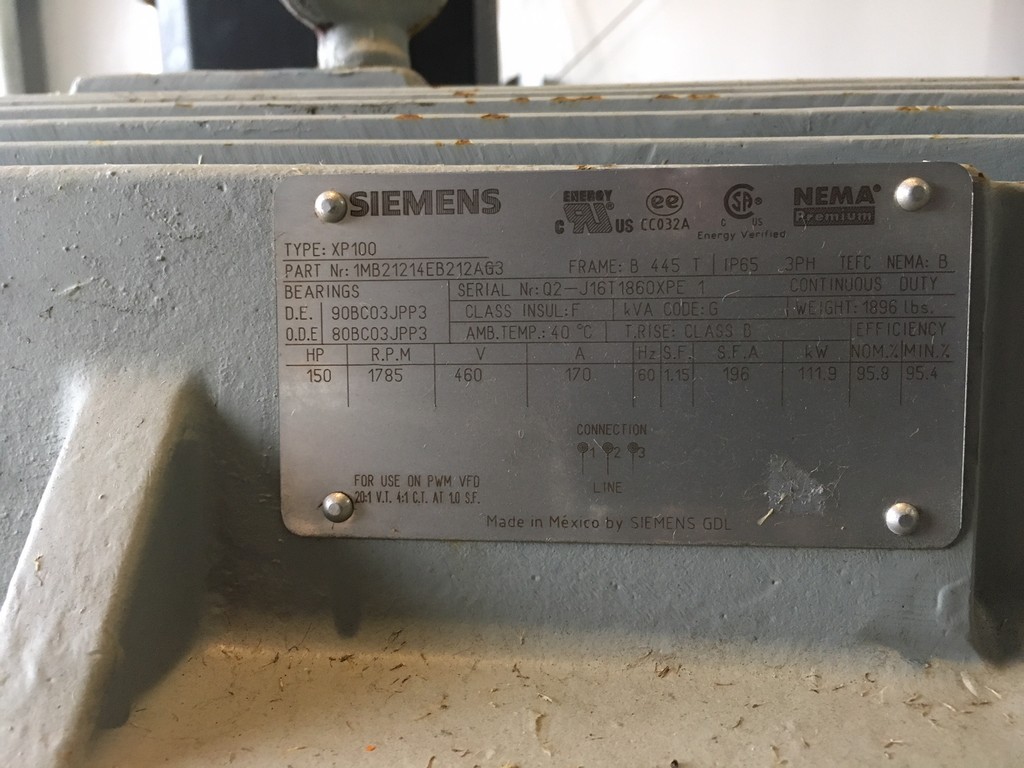

Powered by: SIEMENS EXPLOSION PROOF ELECTRIC MOTOR- Model XP100, Part No. 1MB21214EB212AG3, 150 hp, 1785 RPM Hazardous Location Electric Motor, Phase 3, S/N Q2-J16T1860XPE 1.

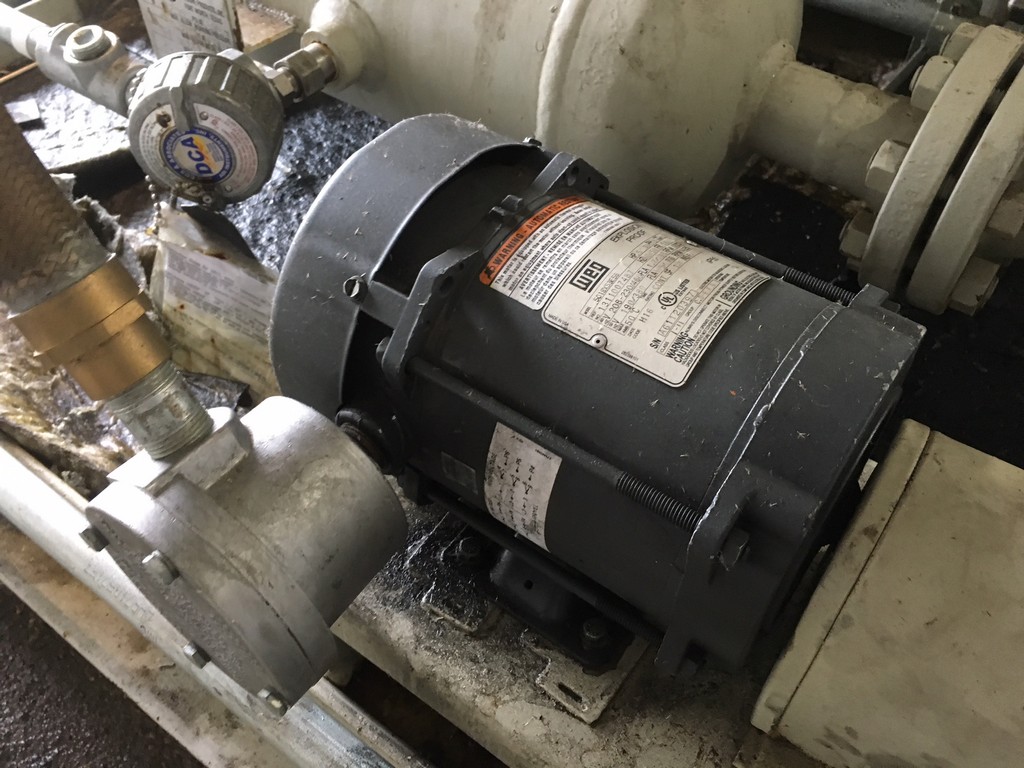

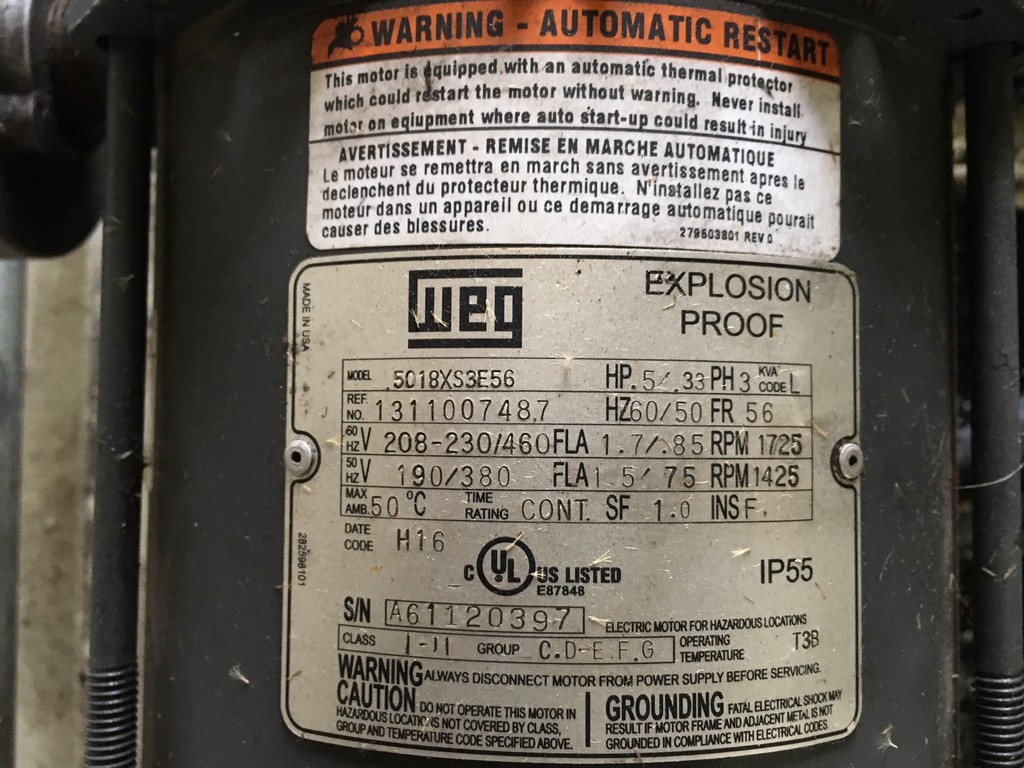

WEG EXPLOSION PROOF ELECTRIC MOTOR- Model- 5018XS3E56, .54 hp Phase 3, 1,725 RPM, S/N A61120397.

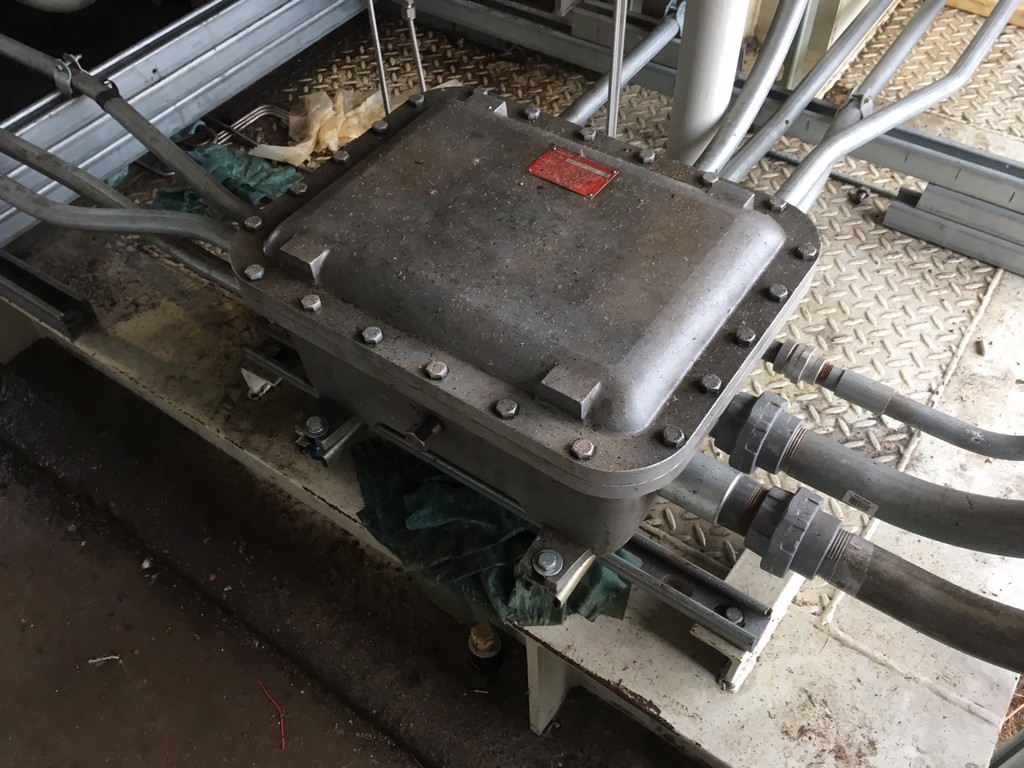

HUBBELL KILLARK HAZARDOUS LOCATION ENCLOSURE- Cast Aluminum Type 4.

Vertical Air Receiver Tank with Necessary Transfer Pumps, Reservoirs, Filters, Piping, Valves and Fittings. Unitized and Installed on 8 ft. Wide x 13 ft. Long x 8 ft. High (approx.) Oilfield Skid having a Diamond Checkered Plate Deck.

Natural Gas Piping Manifold with V-TORK PNEUMATIC ACTUATORS with Flow Cut Off Ball Valves. Does Not Include Necessary Gas Line to Building. See Lot Photos for Included/Excluded Items.

NOTE: BUYER RESPONSIBLE FOR REPAIRING ALL WALL AND ROOF PENETRATIONS WHERE EQUIPMENT WAS REMOVED. REPAIR MUST BE WEATHER TIGHT AND MADE WITH MATERIAL OF SIMILAR CONSTRUCTION.