Lot

4

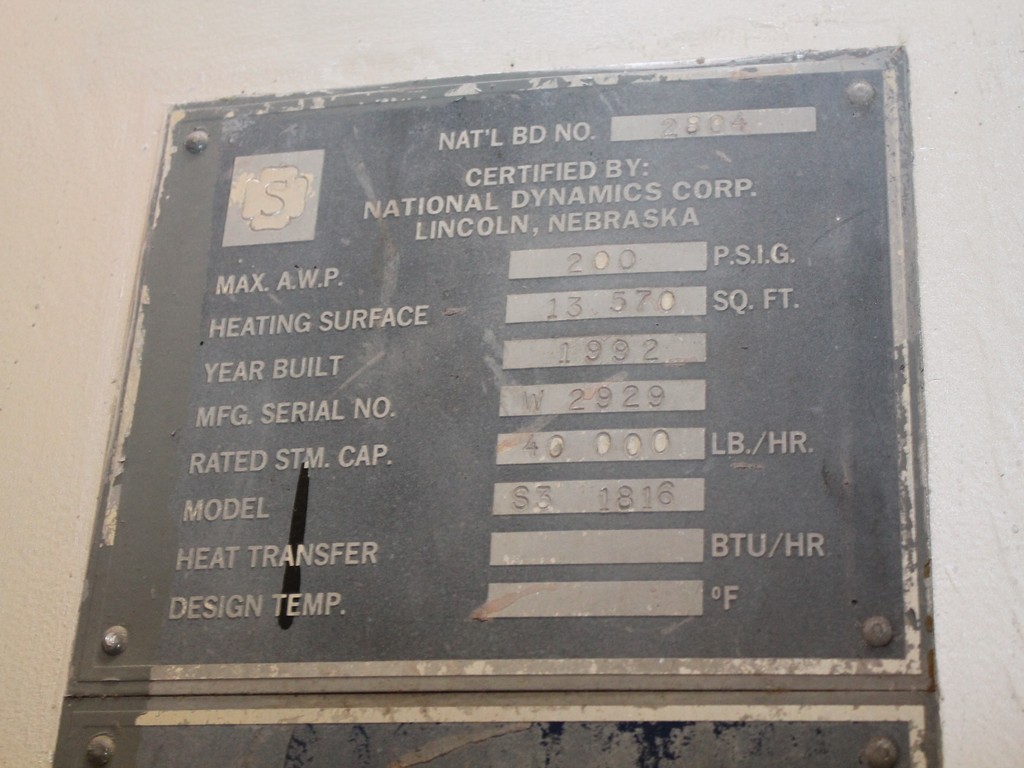

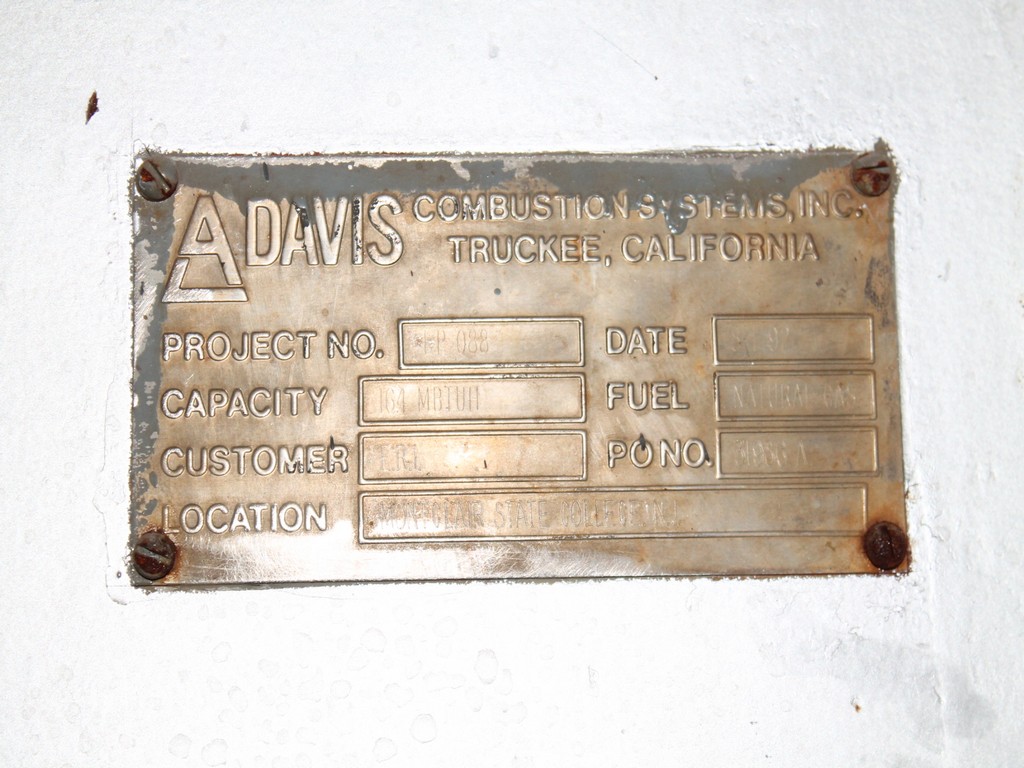

Manufacturer

NATIONAL DYNAMICS CORP.

Name

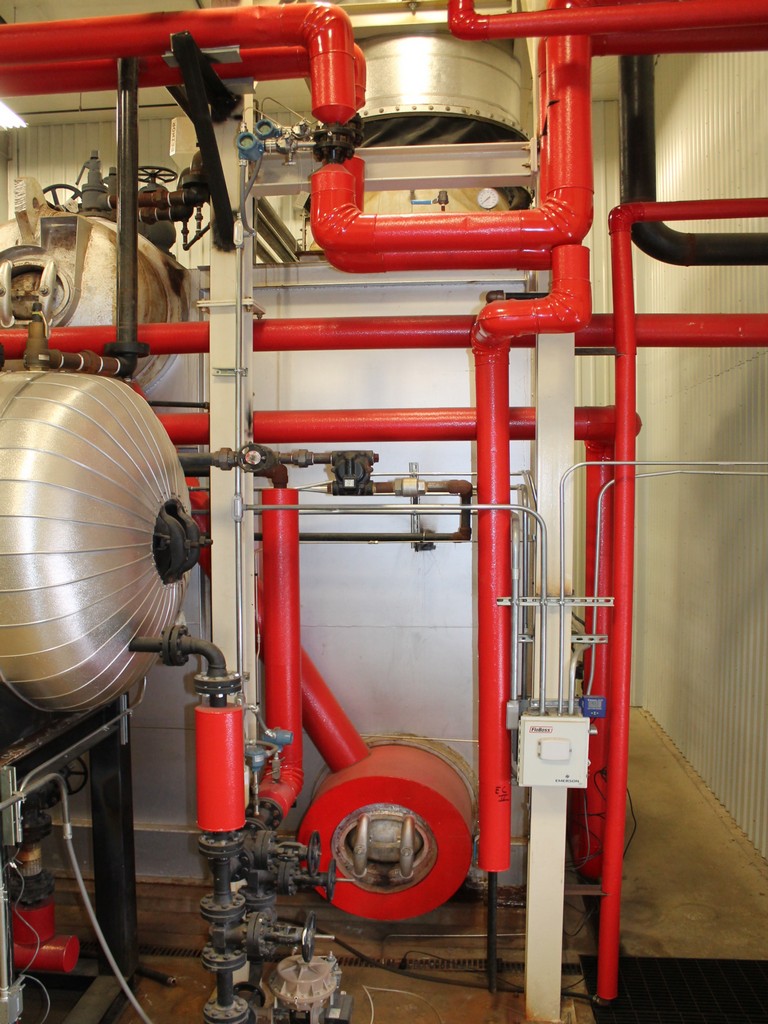

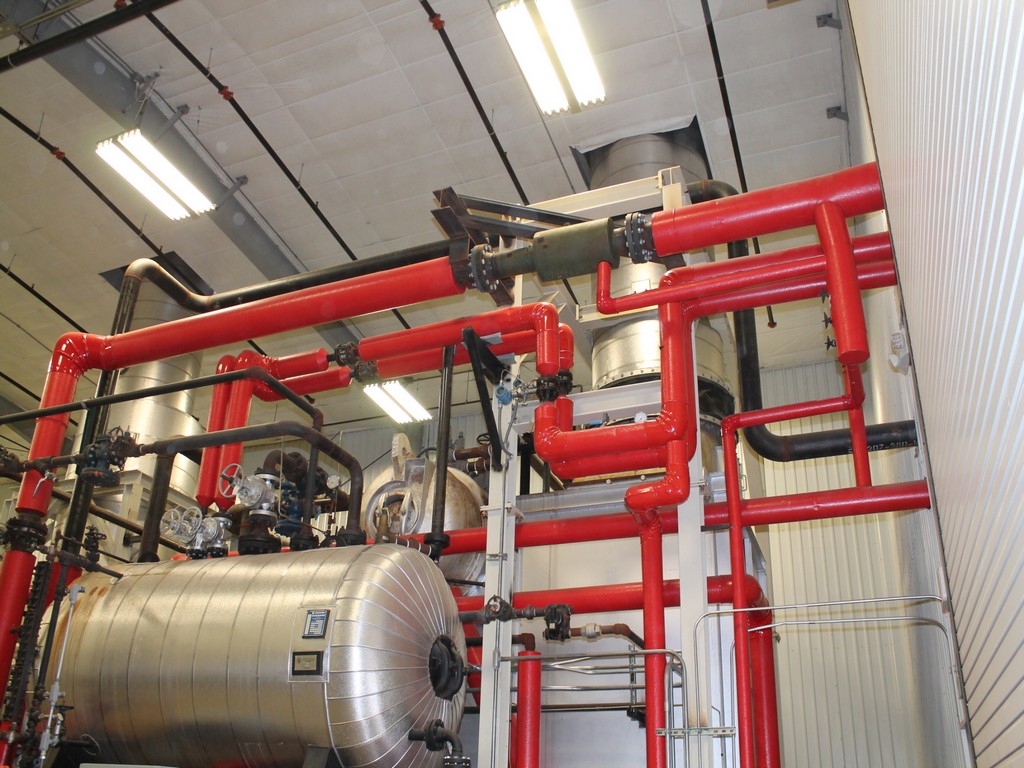

WATERTUBE WASTE HEAT BOILER WITH ECONOMIZER

Model

S-3-1816

Serial

W2929 (Mfg. 1992) Rebuilt 2016

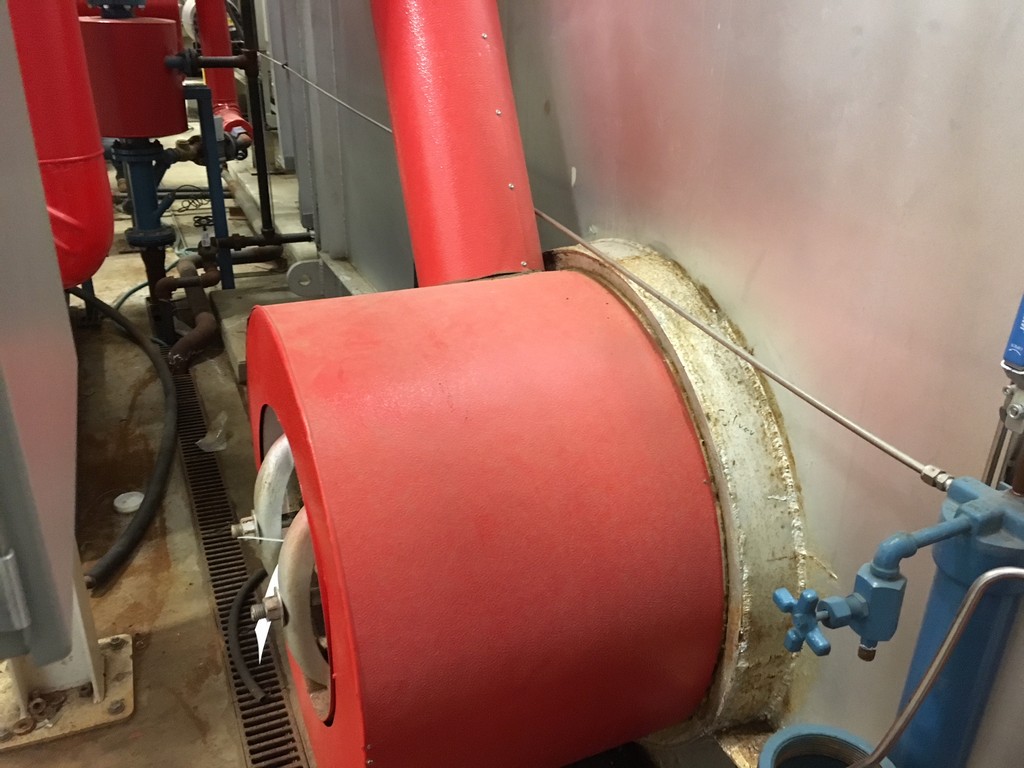

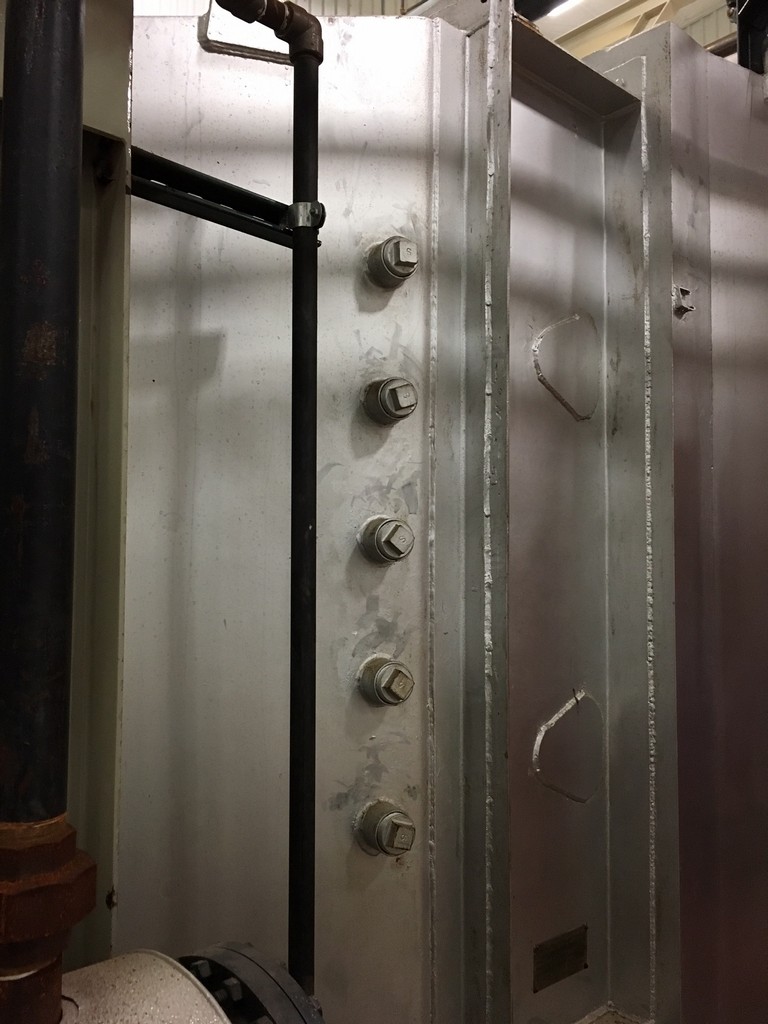

Description

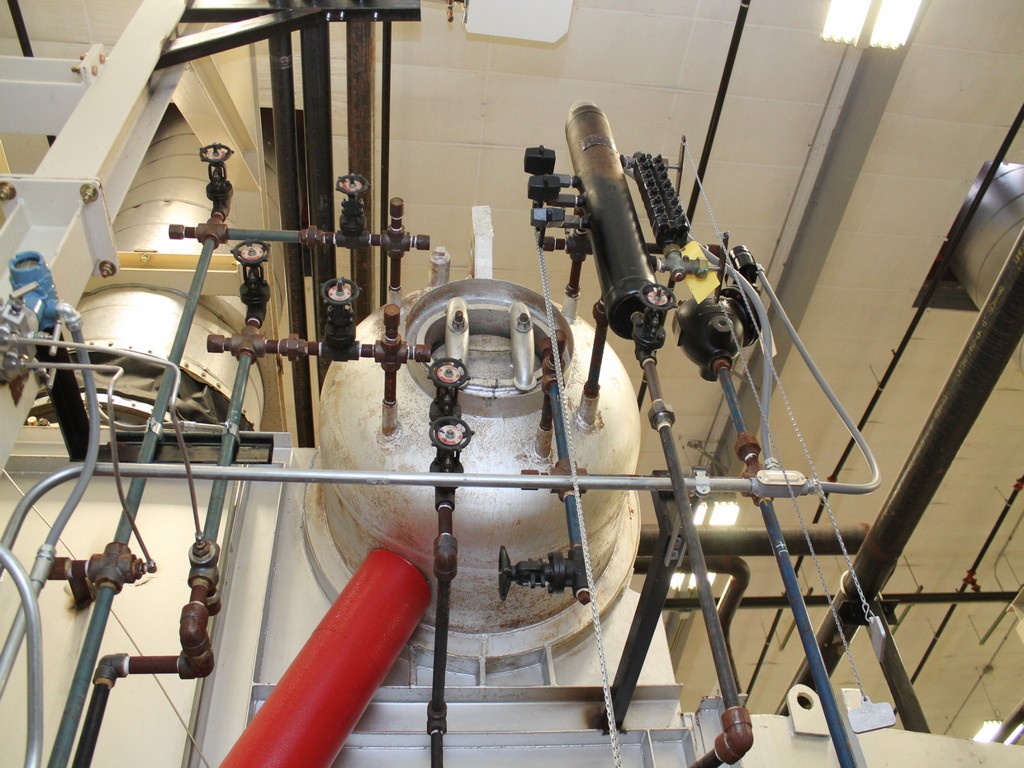

State of Iowa Boiler/Pressure Vessel Registration Number 101642, N/B 2804, Model- S3 1816 Original Specs. Max AWP 200 psig, Heating Surface 13,570 sq. ft., S/N W 2929, (Mfg. 1992), 31' Long x 8'-10" Wide x 18' Tall approx., Rated STM. Cap. 40,000 lbs./hr., ASME Section 1 1989/1990 Boiler was Redesigned and Rebuilt by RASMUSSEN MECHANICAL SERVICES and CLEAVER BROOKS, Date Altered/Rebuilt 10-16-2015, N/B 1065, R Stamp, Code Used For Alteration Performed ASME Section 1 2013, Max. AWP 200 psig, Heating Surface Increased to 16,804 sq. ft., Original Set Up Included a Duct Burner Which Helped Obtain the Rated 40,000 lbs./hr. Predicted Steam Output is Now Rated at 24,450+/-PPH Since the Duct Burner Was Removed from the System. Fin Geometry Was Reconfigured to Increase Steam Production Without the Use of the Original Duct Burner. First 2 Rows Were Changed From Bare Tubes to 3 Fins Per Inch. Fin Density Was Increased on Remaining Rows From 5 Fins Per Inch to 6 Fins Per Inch. Total Surface Area Was Increased From 13,547 to 16,804 sq. ft., Predicted Unfired Steam Capacity Increased Approximately 400 lbs./hr. Completely Re-Tubed in 2015 With All Fins Replaced. Tubes SA-178A 2" OD Fin Material SA-1008 type B. Old Seal Rings Removed From Around the Drum. New Seal Rings Were Installed by Welding. Seal Rings SA-36 10 GA. New Stainless Steel Flow Liner Was Installed from the Diverter to the Boiler.

GENERAL SPECS:

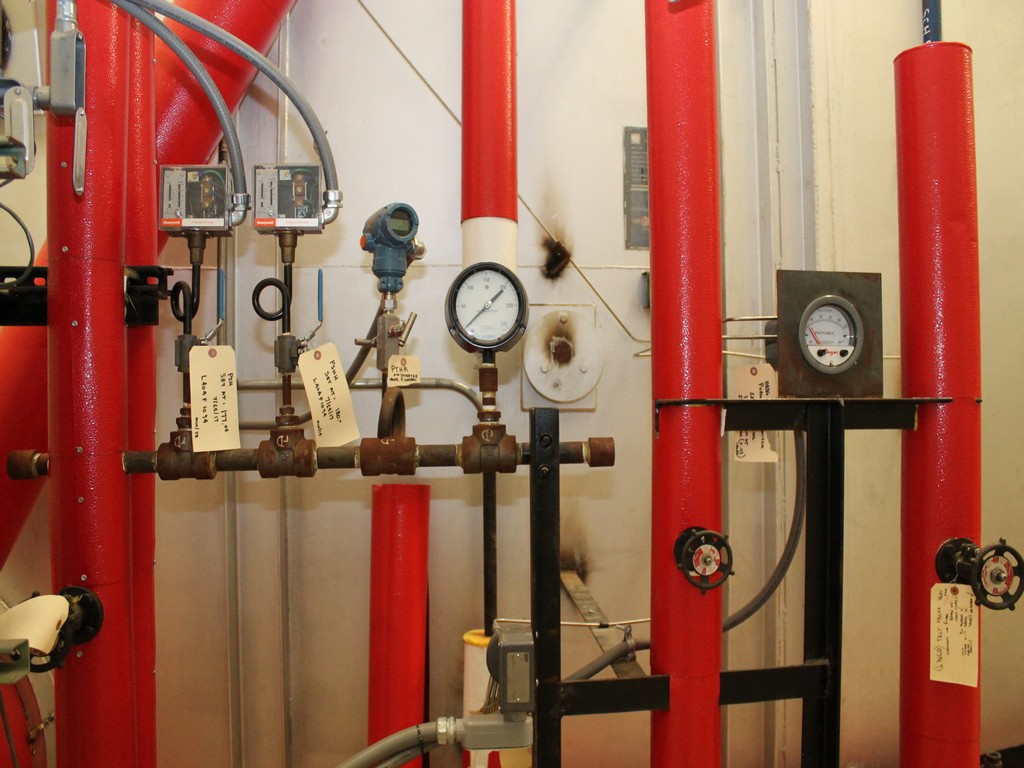

Exhaust Gas Flow 145,508 lbs./hr., Exhaust Gas Temp. 953+/- 10 degrees F, Exhaust Gas Pressure 14.5 psig, Heat Loss 1%, Firing Temp. 1211+/- 10 degrees F, Burner Duty-LHV 11.0MM BTU/H, Steam Pressure 185 psig, Steam Temp. 382+/- 10 degrees F, Steam Flow 24,450 lbs./hr., Feed Water Temp 348+/- 10 degrees F, Blow Down 3%, Elevation 1,155', Drum Press. 185 psig, HRSG Gas Pr. Drop 4.38 in WC, Total Duty 21.5 MM BTU/HR, Pinch 13.9 degrees F, Approach 33.8 degrees F.

PROCESS DATA:

Surface-

Gas Temp In +/- 10 degrees F Evap. 953 / 809, Gas Temp Out +/- 10 degrees F Evap. 809 / 396

Gas Sp. Ht. BTU/LBF 0.275 / 0.265, Duty MM BTU/H. 5.72 / 15.79, Surface Area FT(2) 1,003 / 15,802

Gas Pr. Drop In WC. 0.20 / 4.19, Foul Factor Gas. 0.001 / 0.001

Steam Side-

Steam Press. psig 185 / 185, Steam Flow lbs./hr. 24,450 / 24,450, Fluid Temp. In F 348 / 348, Fluid Temp Out +/- 10 degrees F 382 / 382, Foul Factor Fluid 0.001 / 0.001

Exhaust Gas Analysis-% Volume- Car Dioxide In/Out 3.00, Water Vapor In/Out 6.60, Nitrogen In/Out 76, Oxygen In/Out 14.40, Sulfur Dioxide In/Out 0.0

Drum Specs:

No. 1: Inside Diameter 42", Inside Length 10' 10", Shell Plates SA515/516 GR 70, Thickness .625", Inside Radius 21"

No. 2: Inside Diameter 30", Inside Length 10' 10", Shell Plates SA515/516 GR 70, Thickness .625", Inside Radius 15"

No. 1: Longitudinal Joints 1-2 90% Efficiency, Circum. Joints 3-2 Efficiency 90%, Heads SA516 GR 70, Thickness .75, In. and .675, Type 3, Radius of Dish 37.8, Manholes 2 12" x 16"

No. 2: Longitudinal Joints 1-2 90% Efficiency, Circum. Joints 3-2 Efficiency 90%, Heads SA516 GR 70, Thickness .625, In. and .5625, Type 3, Radius of Dish 27, Manholes 2 12" x 16"

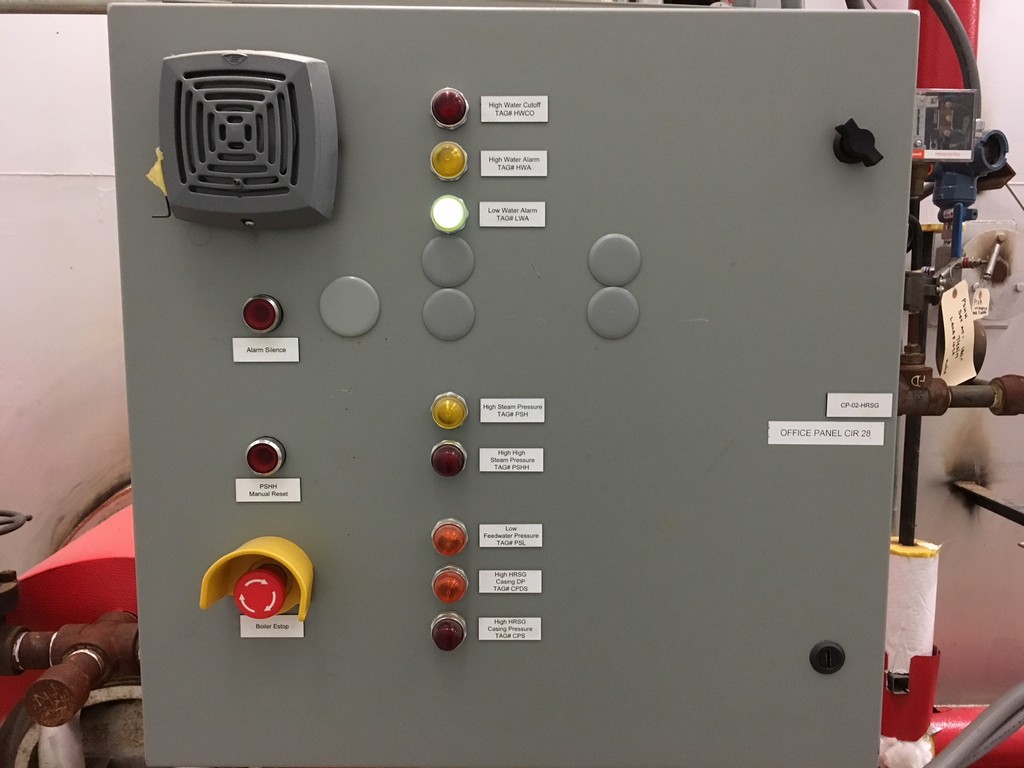

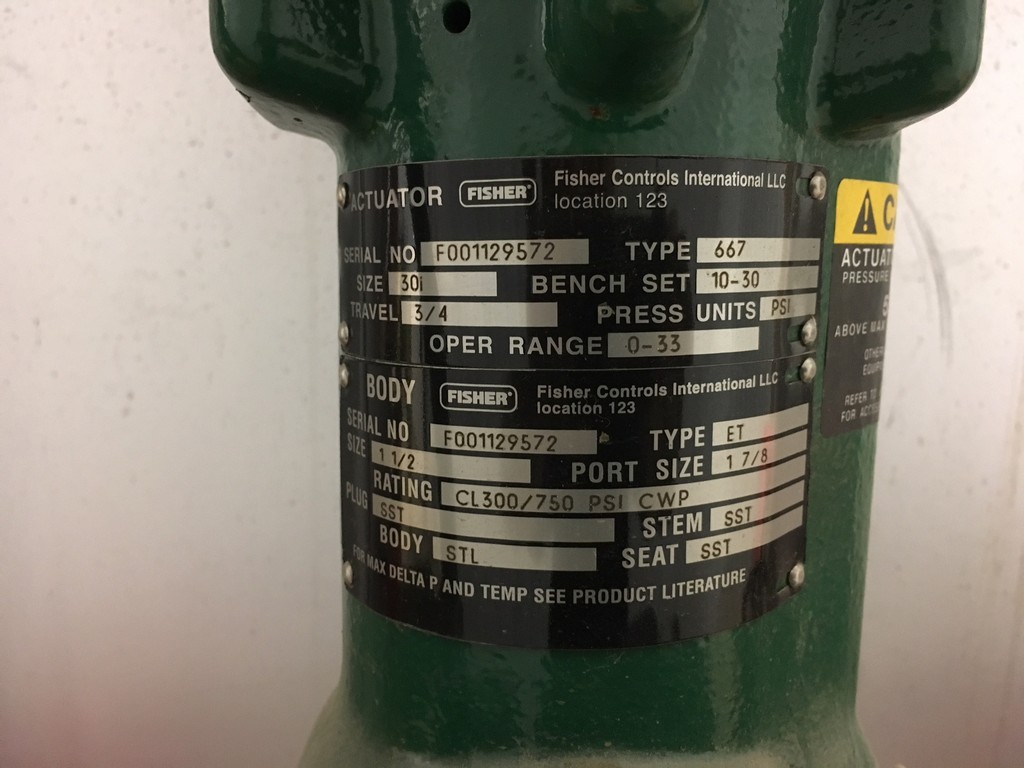

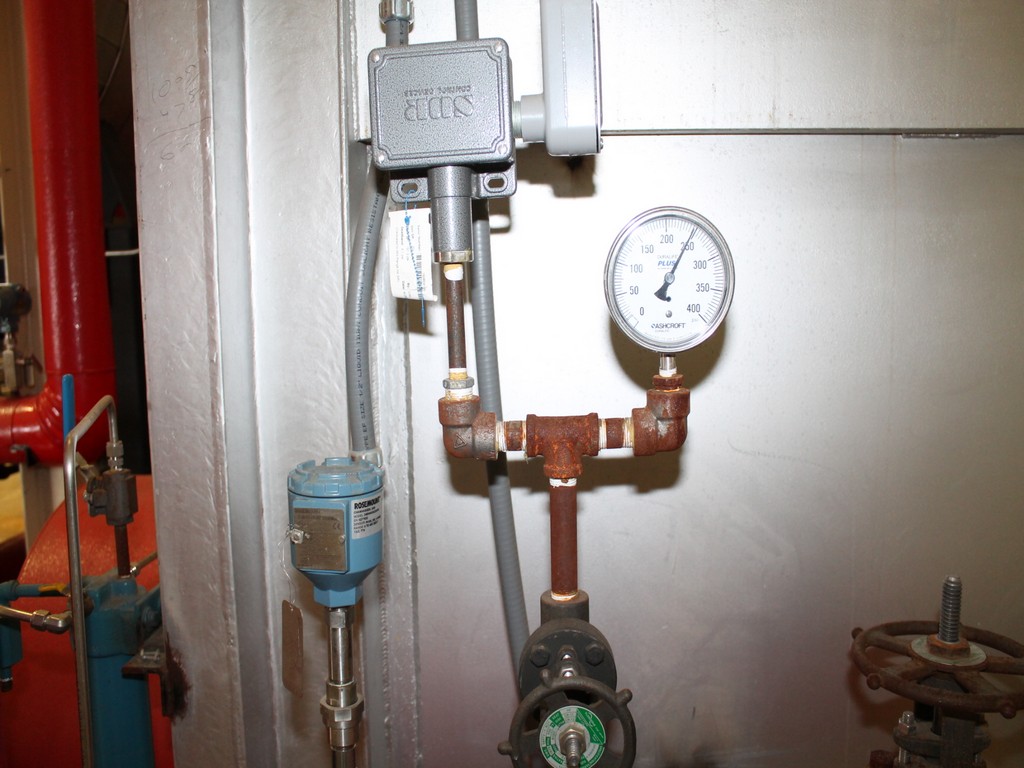

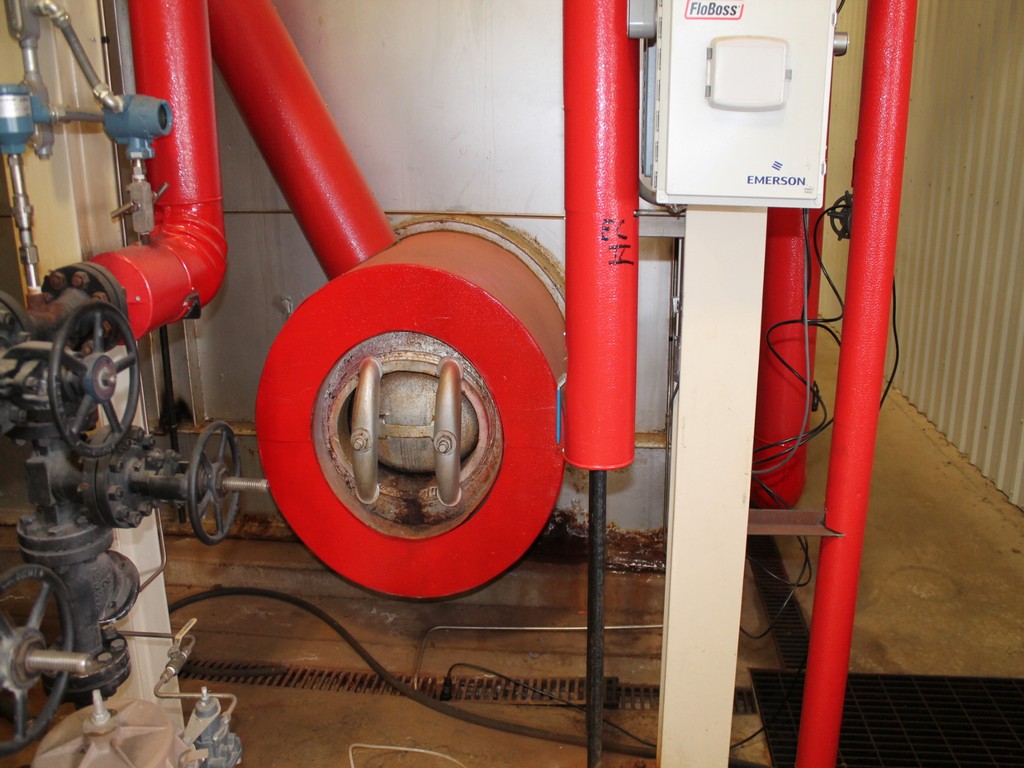

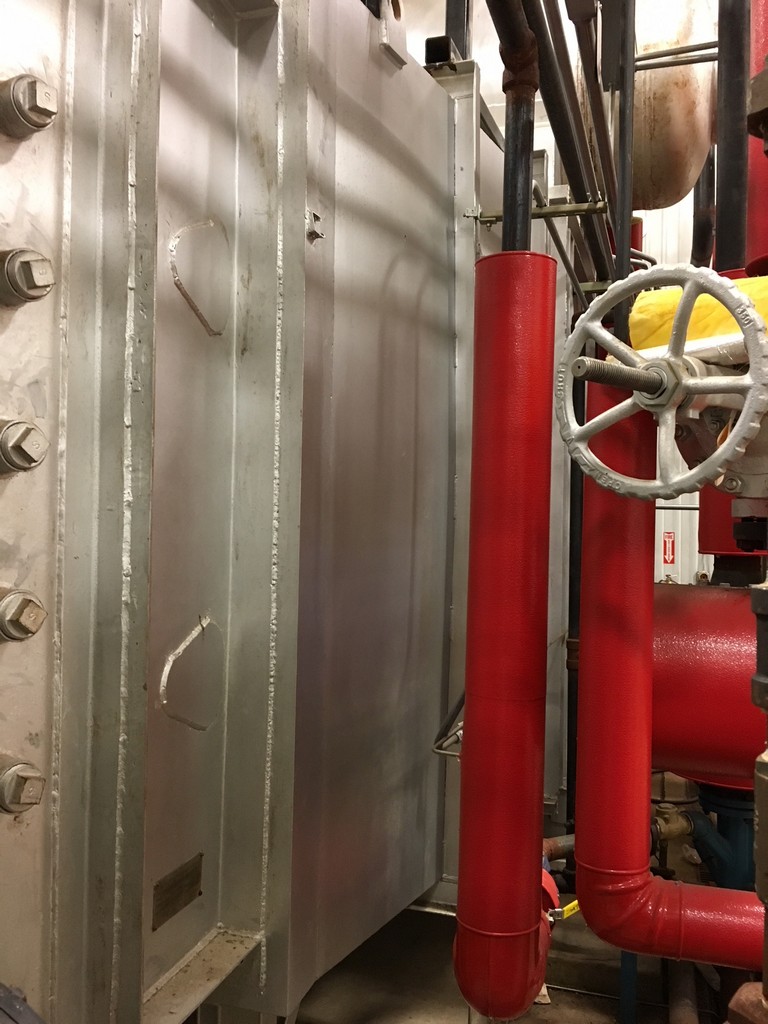

Boiler Mounted Control Panel with Status Lights and Emergency Stop Button, Various Endress Hauser and ROSEMOUNT Digital Sensing/Sending Units, FISHER Control Valve Actuator, S/N F001129572, Type 667, Body S/N F001129572, Type ET, Stem SST, Body STL, With FISHER FieldVue Digital Pneumatic Positioner. EMERSON FLOWBOSS Controller with SENSOREX TX100 2-Wire Digital Transmitter.

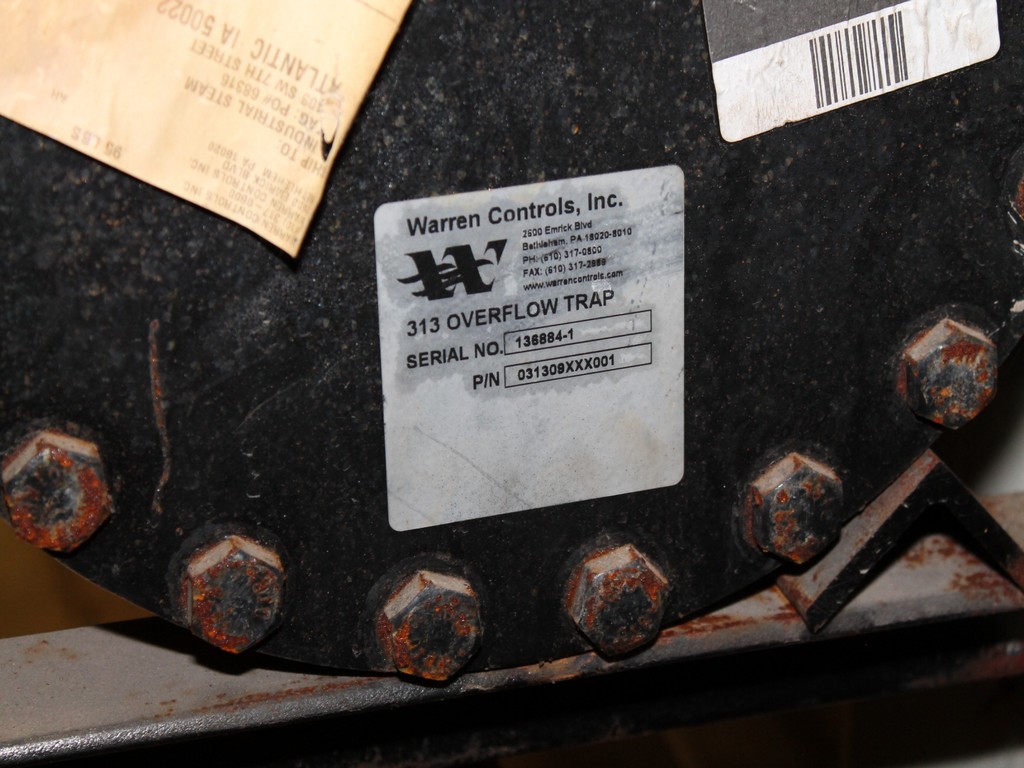

WARREN CONTROLS INC, MODEL- 313 OVERFLOW TRAP, S/N 136884-1, P/N 031309XXX001.

WILSON ENGINEERING- MODEL- 77UM 16" OD CENTRIFUGAL BLOWDOWN SEPERATOR WITH TRF 4 AFTERCOOLER, AUTO TEMP CONTROL PACKAGE, SILENT EXHAUST HEAD, ASME UM STAMP, Certified by IA Manufacturing LLC. Atlantic, IA. Max. Allowable Working Pressure 50 psig at 297 degrees F, Min. Design Metal Temperature -30 degrees F at 50 psig, S/N 24912B (Mfg. 2016).

INCLUDES ALL EXHAUST STACK PIPING INSIDE AND OUTSIDE BUILDING. DOES NOT INCLUDE ANY STEAM AND RELATED PIPING THROUGH WALL TO ETHANOL PLANT.

NOTE: BUYER RESPONSIBLE FOR REPAIRING ALL WALL AND ROOF PENETRATIONS WHERE EQUIPMENT WAS REMOVED. REPAIR MUST BE WEATHER TIGHT AND MADE WITH MATERIAL OF SIMILAR CONSTRUCTION.