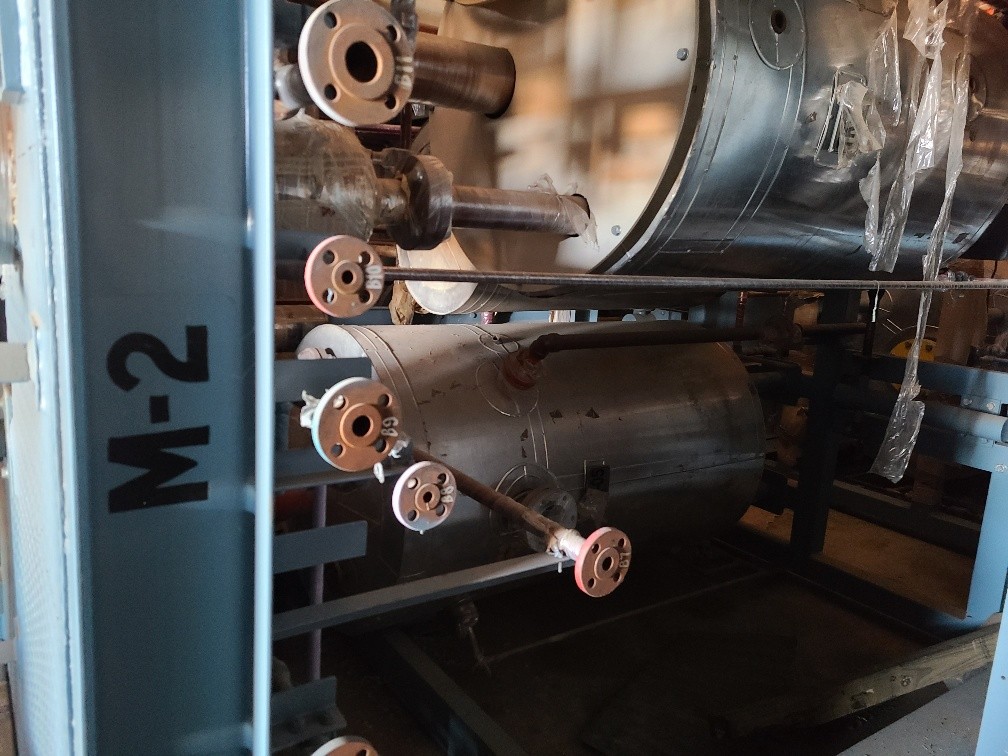

Lot

1

Manufacturer

TECHNOCHEM INTERNATIONAL INC.

Name

NEW NEVER INSTALLED 5 MILLION GALLON PER YEAR BIODIESEL EQUIPMENT PACKAGE

Model

Serial

Description

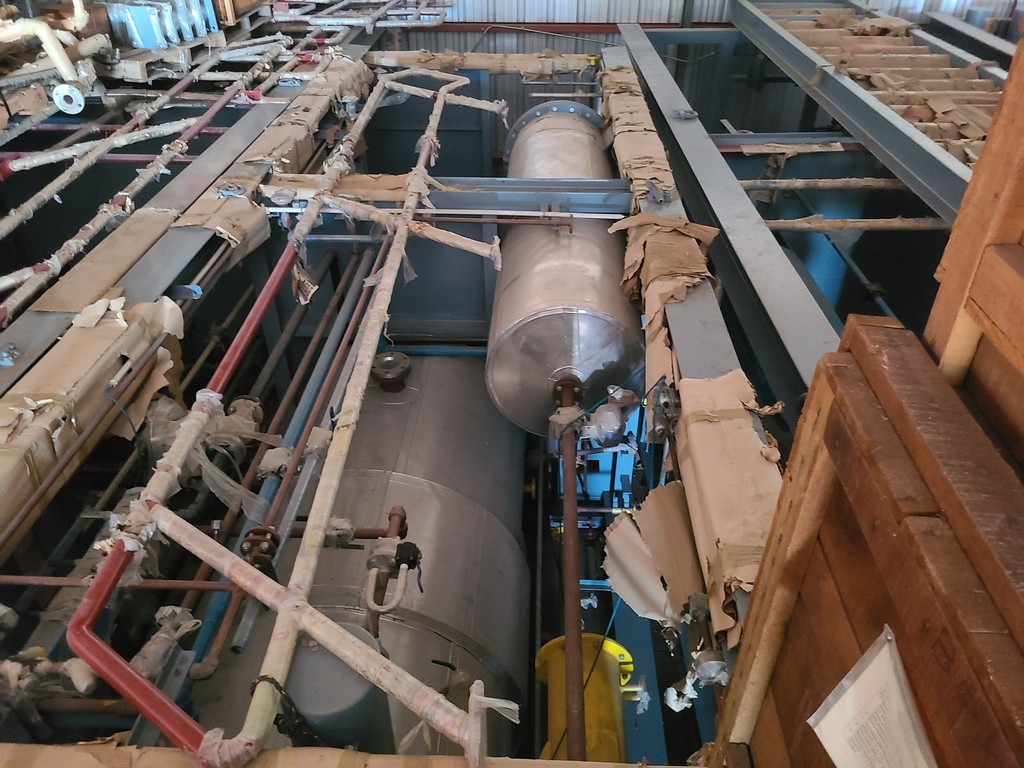

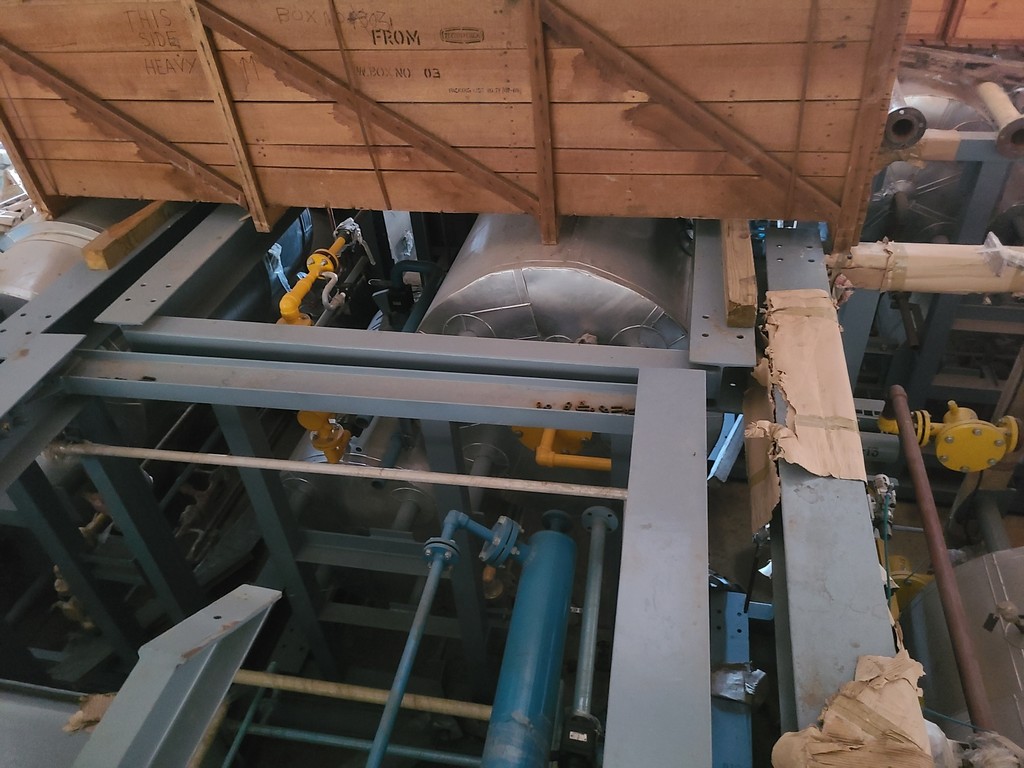

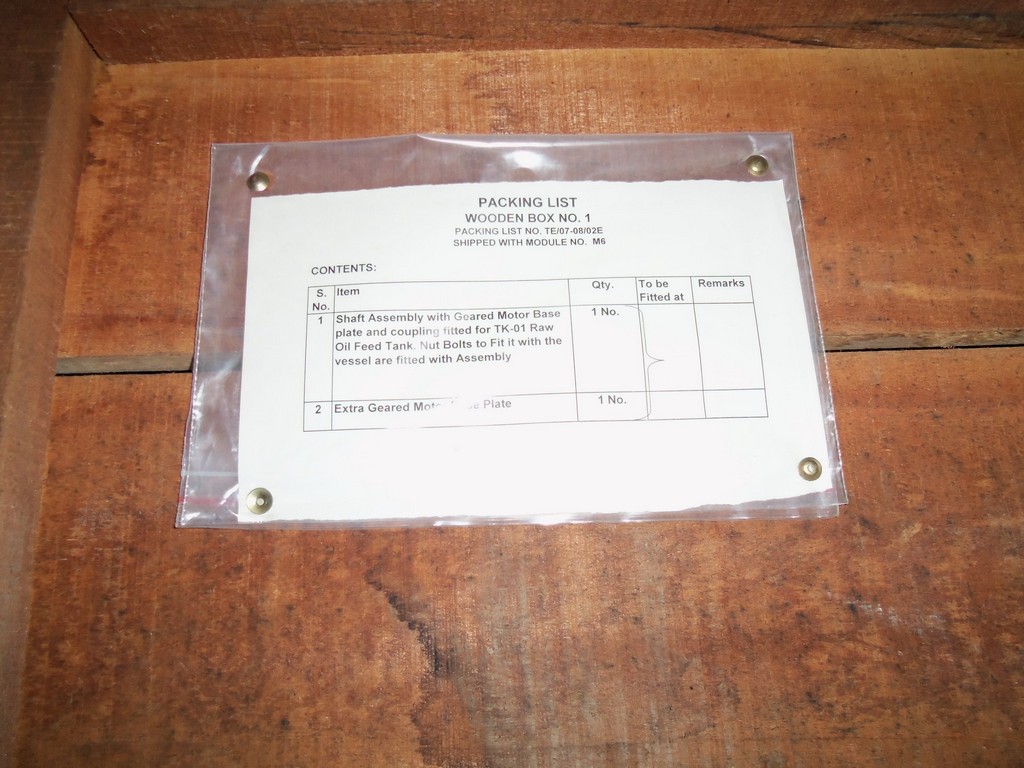

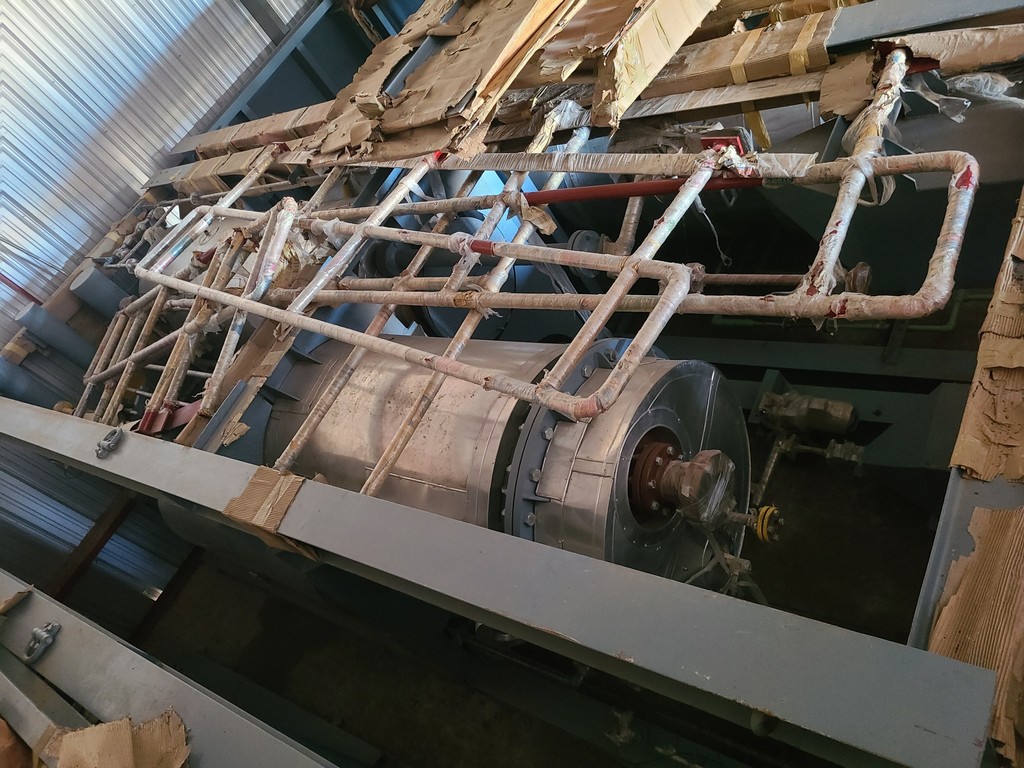

Consisting of but not necessarily limited to: Crude Oil Tank to receive oil from Storage tanks and to supply to process. Pump set in Cast Iron / Carbon Steel construction for pumping of Crude oil to process through flow meter and heater. Plate Heat Exchanger with Stainless Steel plates and Carbon Steel frame for heating of crude oil by steam to desired temperature before mixing of acid to oil. Dosing Pump for transfer of Phosphoric Acid. Mixer in SS 316 construction for mixing of acid with oil. De-gumming Reactor in Stainless Steel fabrication with agitator and motor and sufficient holding capacity to allow maximum reaction of oil with acid. Tank in Carbon Steel fabrication for hot water with steam heating arrangement. Tank in Carbon Steel fabrication for caustic lye. Dosing Pump set in Cast Iron / Carbon Steel construction for transfer of caustic lye. Dosing Pump set in Cast Iron / Carbon Steel construction for transfer of hot water. Mixer of Carbon Steel construction for mixing oil and caustic lye. Contactor in Carbon Steel fabrication complete with agitator and motor and sufficient holding capacity to allow maximum reaction of caustic lye for neutralizing of oil. Pump set in Cast Iron / Carbon Steel for transfer of oil to Centrifuge machine. Shell & Tube Heat Exchanger in Carbon Steel fabrication for heating of oil to suitable temperature for better separation of soap / gum in centrifuge. Tank in Carbon Steel for receiving of soap / gum from centrifuge. Intermediate holding tank in Carbon Steel fabrication to receive de-gummed / neutralized oil from centrifuge. This is to hold oil for 10 minutes. Pump set in Cast Iron / Carbon Steel construction for supply of neutralized or degummed oil from tank to mixing tank of silica earth. Silica Treatment Tank with agitator in Carbon Steel fabrication for reaction of silica earth with oil with suitable residence time. Bin hopper in Carbon Steel fabrication for silica earth dosing. Dosing conveyor of Carbon Steel fabrication for dosing silica earth. Pump set in Cast Iron / Carbon Steel construction with double mechanical seal to pump oil from silica Treatment Tank to filters. Pre-cast tank with Agitator for mixing of filter aid in oil. Pump set in Cast Iron / Carbon Steel construction with double mechanical seal to pump oil with Filter aid to Filters. 2- Bag Filters of Carbon Steel to separate fine earths from oil. Intermediate holding tank (10 minute storage) in Carbon Steel fabrication for receiving oil from Filter. Cyclonic separator in Carbon Steel fabrication to separate oil from vapors going out to atmosphere during steaming of Filters. Slop oil tank to Carbon Steel fabrication to receive oil water mixture from cyclonic separator. Pump set in Cast Iron / Carbon Steel construction with motor for oil from slop tank. Heater in Carbon Steel fabrication for heating oil after silica treatment to temperature suitable for drying. Dryer Vessel in Carbon Steel fabrication operating under vacuum. Pump set with double mechanical seal for transfer of oil from the dryer. Heat Exchanger with Stainless Steel Plates & Carbon Steel frame for cooling of dried to desired temperature for inter-esterification process. Intermediate Holding Tank in Carbon Steel fabrication for receiving oil after dryer. Vacuum System to produce 28" of vacuum in Oil Drying operation. Set of pipelines, valves, fittings, thermometers, pressure gauges for oil, water, steam and chemical lines. Control Panel with set of electrical starters, switches for all motors. Self-supporting structure with operating platform and stairs. Insulation on vessels and pipes as per design. Pump set in Cast Iron / Carbon Steel construction with motor for transfer of oil to reactors. Intermediate holding tank for Methanol. Dosing pump for transfer of Methanol. Dosing pump for transfer of Sodium Meth-oxide Catalyst. Mixers for mixing of methanol and catalyst. Esterification Reactor in Carbon Steel fabrication with agitator and motor and sufficient holding capacity to allow maximum reaction of oil with methanol. 2- Coalescers for separations of biodiesel and glycerin phases. One set of Elements included in supply. Tank in Carbon Steel with Agitator for receiving of Methyl Ester from Coalescer. Dosing Pump for Supply of dilute acid to Methyl Ester in Tank. Pump set in Cast Iron / Carbon Steel construction with motor for transfer of Methyl Ester to Distillation Column for recover of methanol. Tank in Carbon Steel with Agitator for receiving of Methyl Ester from Coalescer. Pump set in Cast Iron / Carbon Steel construction for pumping of Glycerin phase to Settling Tank for removing Fatty Acids. Settling Tank for Glycerin phase in Carbon Steel fabrication. Pump set in Cast Iron / Carbon Steel construction for pumping of Glycerin phase for Methanol Recovery. Cartridge Filter for Glycerin Phase after acid treatment to remove salts. Heat Exchanger for heating the Biodiesel Phase to temperature suitable for Evaporation of Methanol. Distillation column for recovering Methanol from Biodiesel. 2- Condensers for condensing Methanol Vapors. Regenerative Heat Exchanger to recover heat from Methyl Ester from column. Reboiler for heating of Biodiesel for recirculation in column. Tank for Condensed Methanol from Condensers. Pump set in Cast Iron / Carbon Steel construction for pumping of biodiesel to Silica Treatment Tank. Silica Treatment Tank with Agitator in Carbon Steel fabrication for reaction of Silica Earth / Magnasol with biodiesel with suitable residence time. Bin Hopper in Carbon Steel fabrication for Silica Earth dosing. Dosing Conveyor of Carbon Steel fabrication for Silica Earth dosing. Pump set in Cast Iron / Carbon Steel construction with double mechanical seal to pump biodiesel with Silica Earth / Magnasol to Filters. 2- Cartridge Filters of Carbon Steel body to separate fine earths from biodiesel. Intermediate Holding Tank (10 minute storage) in Carbon Steel fabrication for receiving biodiesel from Filter. Pump set in Cast Iron / Carbon Steel construction for pumping of biodiesel to dryer. Plate Heat Exchanger with Stainless Steel plates and Carbon Steel frame for heating of biodiesel by steam to desired temperature for removal of moisture in dryer vessel. Dryer to operate under vacuum for drying of biodiesel. Pump set in Cast Iron / Carbon Steel construction for pumping of biodiesel from dryer. Heat Exchanger to cool biodiesel for storage. Intermediate tank to receive cooled biodiesel. Pump for transfer of biodiesel to Storage Tanks. Vacuum System for Methanol Recovery Column from biodiesel. Vacuum System to produce 28' of vacuum in Oil Drying operation. Set of pipelines, valves, fittings, thermometers, pressure gauges for oil, water, steam and chemical lines. Control Panel with set of electrical starters, switches for all motors. Self-supporting structure with operating platform and stairs. Insulation on vessels and pipes as per design. Heat Exchanger with Stainless Steel plates and Carbon Steel frame for heating of Glycerin Phase by steam to desired temperature for feeding to Distillation Column. Distillation Column with trays for recovery of methanol from Glycerin Phase. Condenser for methanol vapors. Pump for supplying methanol to next column or for return to column. Reboiler for Glycerin using steam for heating. Pump for removal of 50% Glycerin. Intermediate holding tank for recovered Glycerin. Distillation Column for purification of Methanol to 99.5% purity. Methanol Condenser. Re-Boiler using steam for heating of water in 3rd column. Pump for discharge of waste water. Intermediate holding tank to receive 99.5% Methanol. Pump for methanol to transfer for reuse or for return to column.