Lot

220

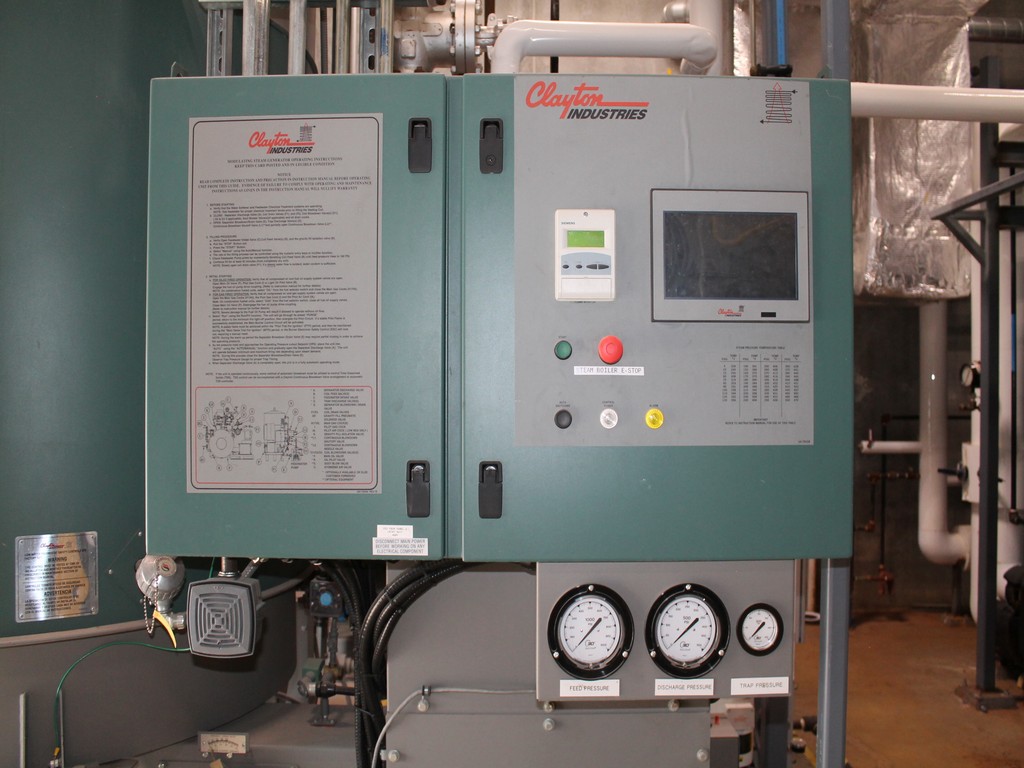

Manufacturer

CLAYTON INDUSTRIES

Name

LOT STEAM GENERATOR

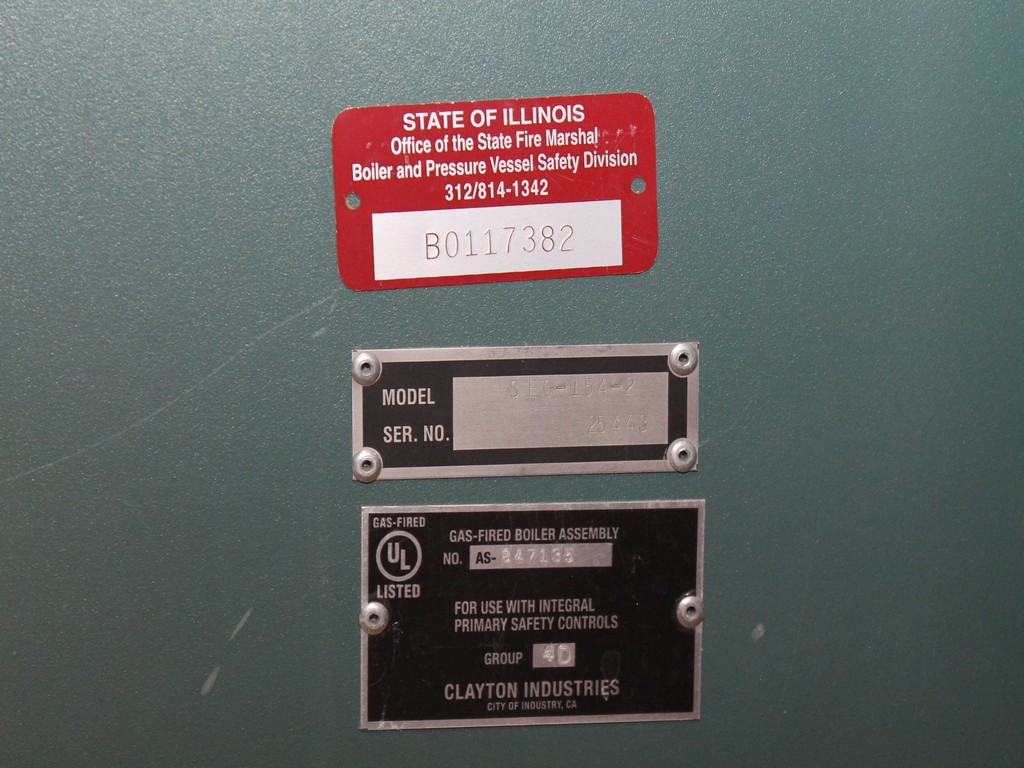

Model

SEG154-FMB

Serial

Description

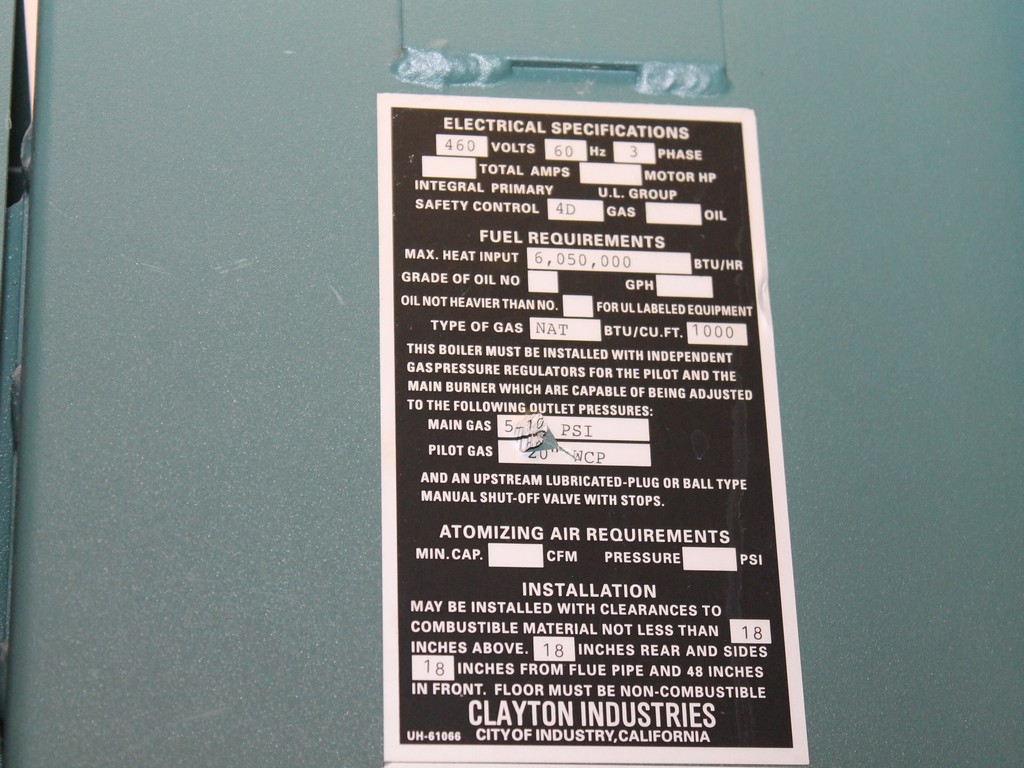

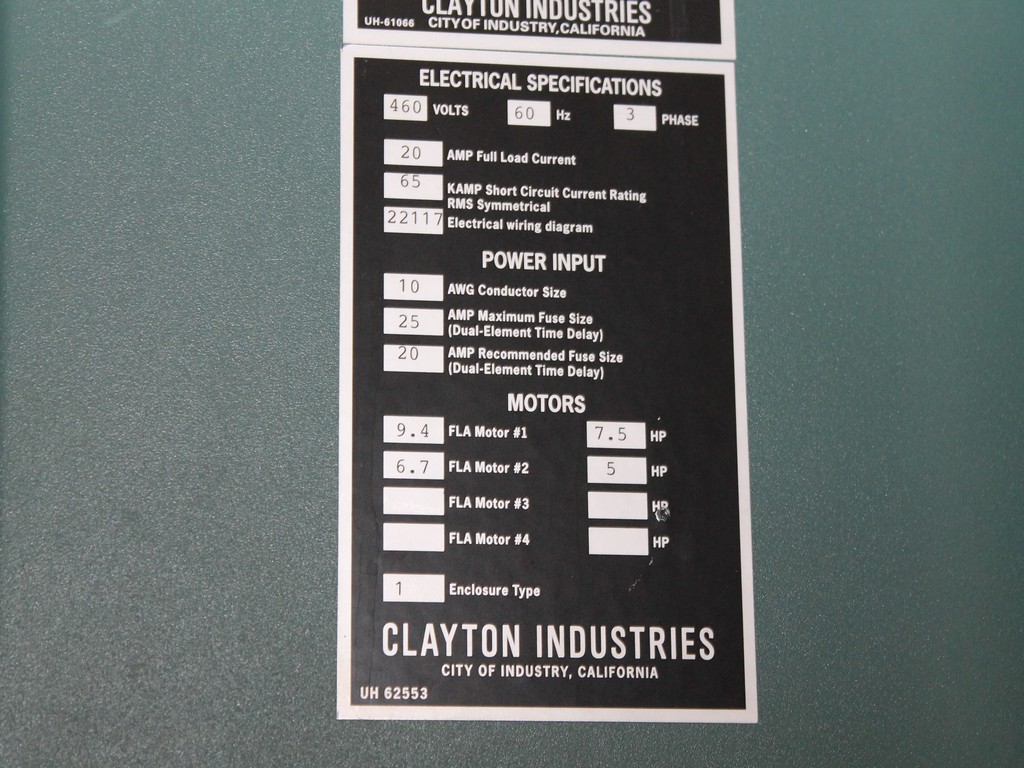

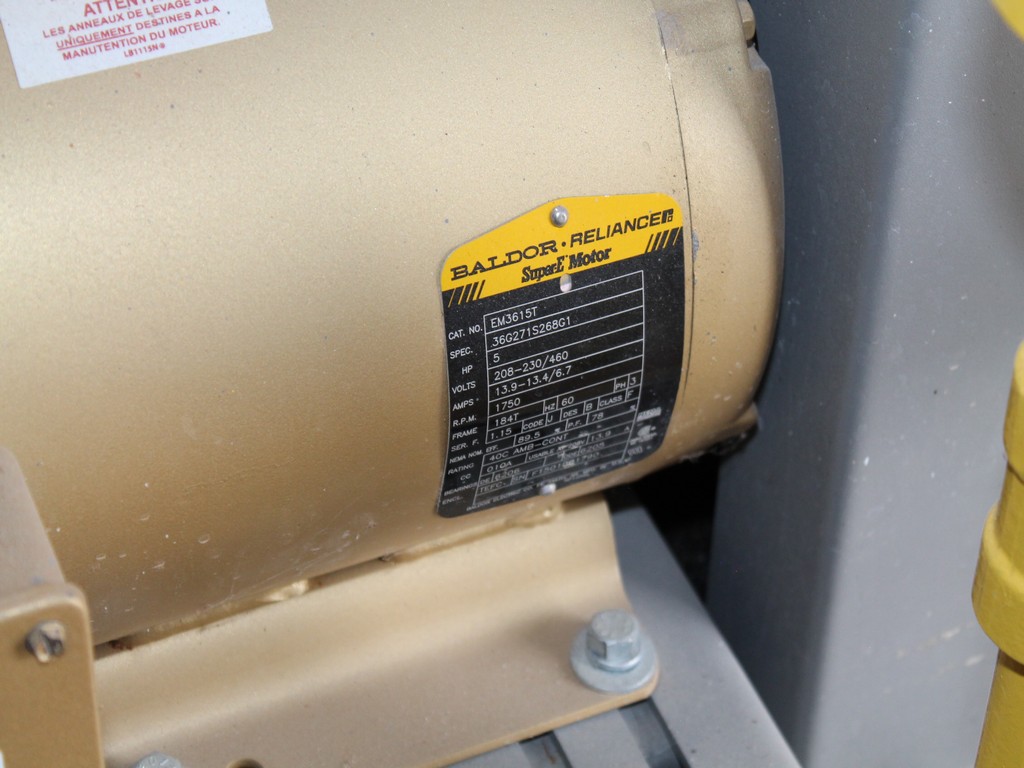

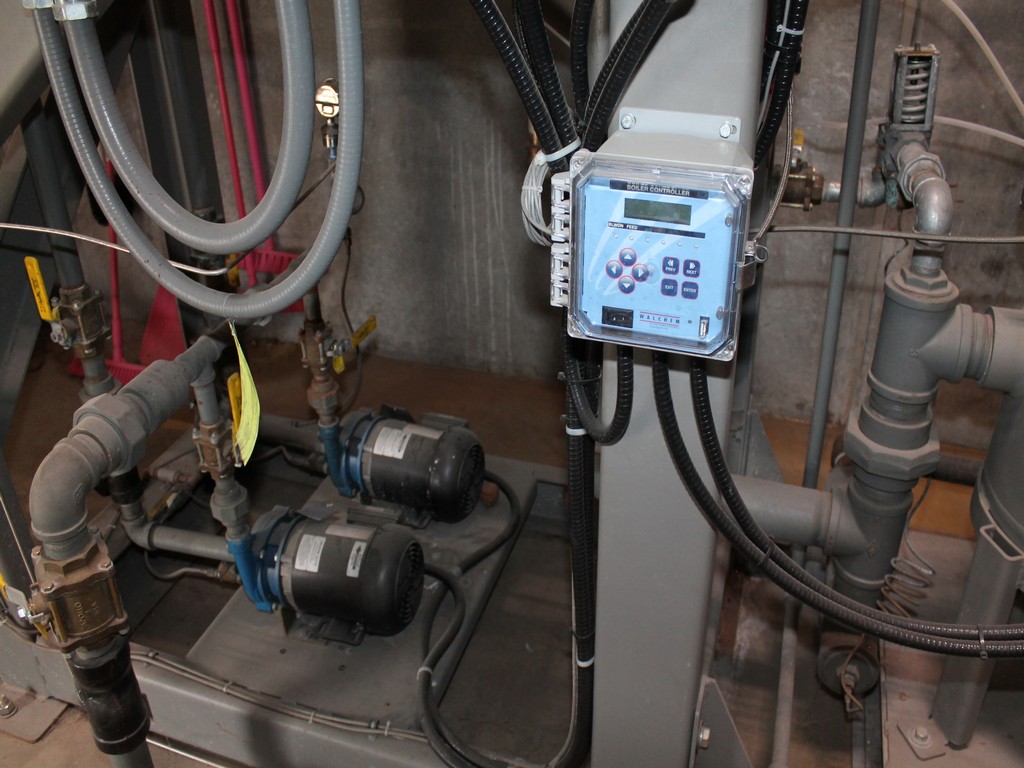

Consisting of but not limited to: 150 Horsepower, Natural Gas Fired, 5907355 Input BTUs, PLC, Siemens LMV5 Low Nox FMB Burner and Super Economizer; Feedwater Skid Supply System with Head Tank and Hot-Well Tank, (2) Pumps, etc. Detailed Specifications: 1 MODEL EG154-2 STEAM GENERATOR, Rated Boiler Horsepower: 150 BHP, Equivalent Steam Output: 5,175 pph, (from and at 212EF feedwater and 0 psig steam), Design Pressure: 200 psig, Operating pressure: 150 psig, Safety Valve Set: 200 psig, Fuel Specification: Natural Gas (1,000 BTU/CF),Required Minimum Gas Pressure (at gas train inlet): 5 psig, Electrical Requirements: Voltage 460/60/3, Constructed per ASME Section I and National Electric Code, Hartford Tested and Inspected, FM and CSD-1 Compliant. MOUNTED ON A SINGLE FRAME: Monotube Heating Coil with Integral Burner Base Steam Separator, ASME stamped w/Safety Relief Valves, Natural Gas Fuel Train and Modulating Burner with 5:1 Turndown Ratio, Forced Draft Blower and ODP Motor. Positive Displacement Main Feedwater Pump and Variable Speed ODP Motor (on separate skid), Control Cabinet with Operator Interface Keypads, Compusteam PLC Controls, Hour Meter and Alarm Horn, Pilot Gas Regulator (5 to 60 psig supply pressure). Main Gas Regulator - Built-in (5 to 10 psig supply pressure), Feedwater, Steam & Trap Pressure Gauges (locally mounted), 10" Color Touch Screen Operator Interface. ACCESSORIES INCLUDED WITH STEAM GENERATOR: Gauge Panel Kit. Centrally located Panel for Steam, Feedwater and Trap Pressure Gauges. Pump Oil Level Switch. Provides automatic unit shutdown for high or low feedwater pump crankcase liquid level condition. Dial thermometer mounted on steam separator for monitoring separator steam temperature. Installation Valve Kit: includes Coil Gravity Drain, Coil Drain (back flow), Separator Drain and Trap Outlet Valve. Feedwater Valve and Strainer Kit, includes shutoff valve and y-type strainer. Steam Header Valve, globe type with chain operator. Back Pressure Regulator, for up to 250 psig design pressure. Auxiliary Relay dry contact for activation of booster pump(s) and/or chemical pump(s) circuit when power is applied to unit. Motorized down draft damper, 18 in., 304 SS construction with flanged connections. Brushless DC motor driven actuator, on-off, spring return fail-safe design, with proof of opening signal relay. OPTIONAL ACCESSORIES: Upgrade to PLC Level II system from standard PLC Level I, includes additional sensors for monitoring of stack temperature, coil temperature, feedwater inlet temperature and pressure. Upgrade to PLC Level III from standard PLC Level II. Includes additional sensors for monitoring of primary fuel and steam flow (includes PLC Level II). Ethernet or Modbus connectivity for remote access to display steam generator parameters. SE Super Economizer Coil Section. Provides additional heating surface to improve thermal efficiency. Supported by main heating section, includes outer shell and interconnecting piping. One (1) set of 18" ID, double-wall, positive pressure, breeching and stack. Boiler stack shall be manufactured from type 304 Stainless Steel inner-wall with Aluminum-zinc coated outer wall. The flue material is double-wall, 2-inch mineral fiber insulated chimney. For premium corrosion resistance and durability, the inner flue is constructed from .035" 304 stainless steel. This is coupled with a .018" Aluminum-zinc coated outer casing. All stack and breeching material shall be UL listed to UL 103 and UL 1978 and ULC C959, ULC S604. This stack package shall consist of 18" ID; Total estimated length ~28' including riser off boiler; with boiler adapter, adjustable lengths, 90? Tee w/ barometric damper, firestop, storm collar, roof flashing, anchor plate, support clamps, and sealants. FEEDWATER TREATMENT SYSTEM COMPONENTS: Hotwell, Horizontal atmospheric feedwater tank, with trim and heater kit for feedwater pre-heating and chemical mixing, and connection for condensate return. Trim kit includes water level sensor and solenoid valve, a dial thermometer, and water level gauge glass. Heater kit includes a temperature switch, solenoid valve and pipe fittings. Suitable for up to 200 connected BHP. Requires 110V/1/60 power. Two (2) Booster Pumps, to provide sufficient NPSH for main positive displacement feedwater pump(s), all iron construction, centrifugal-type with high temperature tungsten carbide/carbon viton mechanical seals and motors. Suitable for up to 150 connected BHP. Blowdown Tank with automatic discharge temperature control valve, for collection and cooling of blowdown water. Constructed per ASME, National Board stamped and approved. Liquid Chemical Injection Pump(s), positive displacement with ceramic ball valves & Teflon seats. Pump capacity: 14.4 gpd, 115V /50-60hz/1ph. Automatic TDS Controller. Includes TDS electrode sensor and motorized dump valve for control of total dissolved solids (TDS) level. SKID MOUNTING OPTION: Generator / Feedwater System Skid Mounting - EG-154 unit. The steam generator and feedwater components will be mounted on a sectional support frame with deck plating. TOTAL: $137,378. EG154-2 STEAM GENERATOR, FEEDWATER SYSTEM, SKID MOUNTING